(Requires paid member status to access.)

by Ian Stokes…..

After several times cleaning and/or resurfacing the contacts of the Ducellier starter motor switch on my 1936 7C, I realized there might be a better way to get a long term fix. The problem was the contact material – just plain brass corrodes and gets pitted by the high currents it has to handle. The symptoms were very similar to those of a dying battery – the starter could hardly turn the engine. So I realized that the contact surfaces of the switch had to be improved.

A Google search “contact materials electrical switches” showed that silver alloys are well suited to use in high-current DC switches. For example see: https://www.pepbrainin.com/technical-resources/electrical-contact-materials/

In their table of different alloy compositions, I saw this Silver-Cadmium alloy: “85Ag, 15Cd: low material transfer, resists sticking, used in automotive relays, DC motor controls and other DC devices with high surge currents.”

I had some silver solder with composition 45% Silver; 24% Cadmium (remainder Copper and Zinc). Probably close enough.

How to apply the high melting point solder to the switch contacts? Especially on the motor side I didn’t want to remove the contact post. My solution was to use a thin (1 mm thick) piece of copper as ‘substrates’, then soft solder them to the dressed original contacts. First, I ran a layer of the silver solder over one side of each of the copper substrates. After soft-soldering them to the original contacts I dressed the silver solder layer flat with a file and re-assembled the switch. An easy project – the hardest part was getting clearance to remove the starter by removing the rear engine mount and jacking up the engine. So far the renovated starter switch is working just fine.

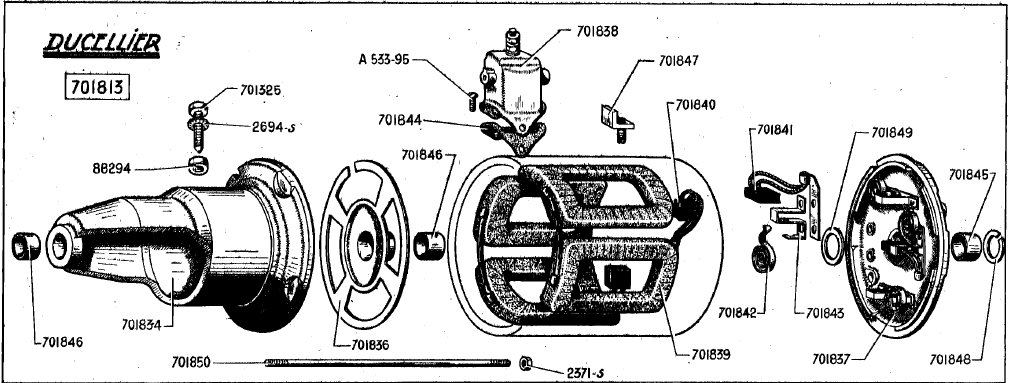

Figure 1: Ducellier Starter Motor (from Citroën Parts Catalogue)

Figure 1: Ducellier Starter Motor (from Citroën Parts Catalogue)

Figure 2: Overall view of starter with switch on top.

Figure 2: Overall view of starter with switch on top.

Figure 3: The starter motor-side contact resurfaced.

Figure 3: The starter motor-side contact resurfaced.

Figure 4: The switch-side contact resurfaced.

Figure 4: The switch-side contact resurfaced.