by Ken Nelson…..

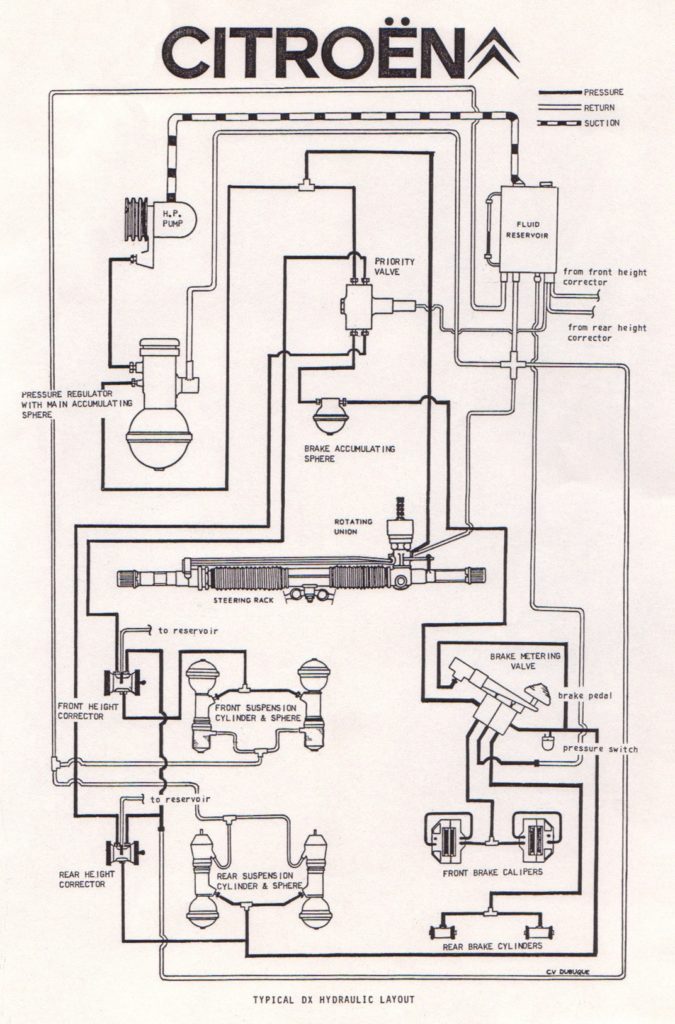

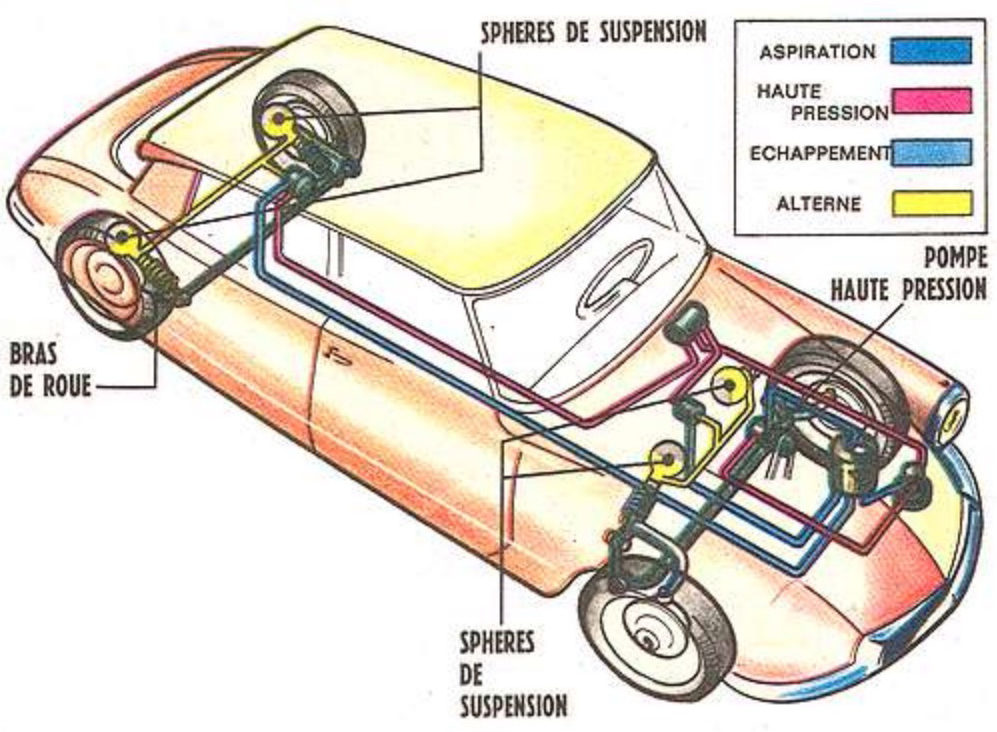

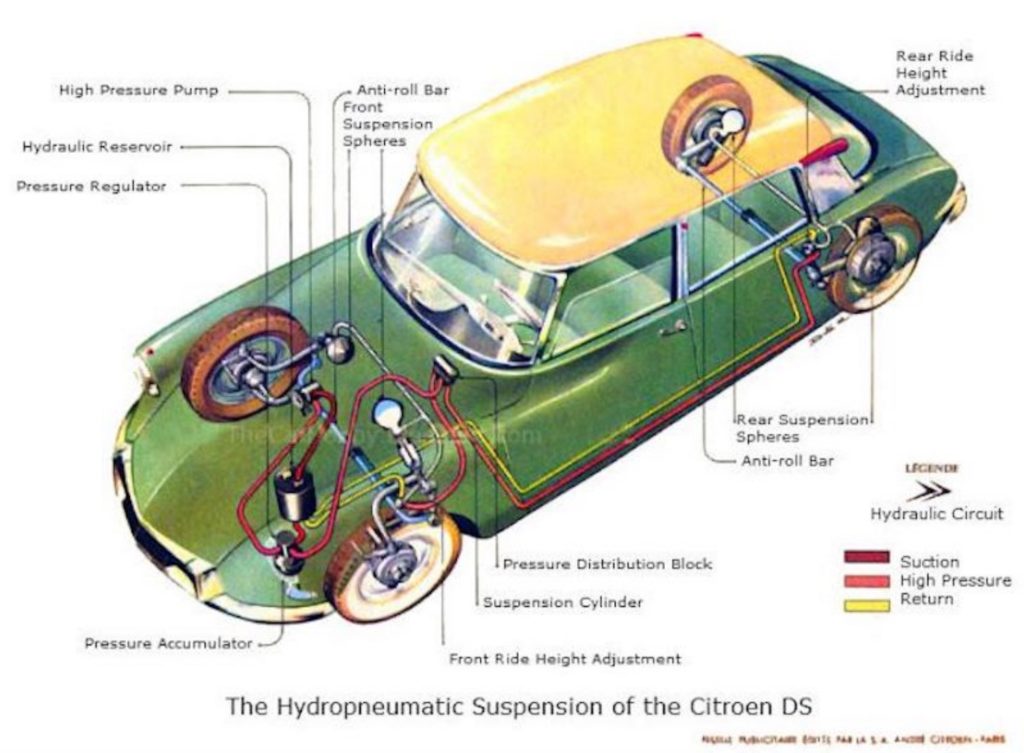

Regarding the brake button advantages, the hydraulic system (steering, brakes, suspension) is a high-pressure system – at 2500 psi (IIRC). Braking force is modulated by the foot pressure applied to the button, rather than how far the pedal travels. In a panic stop situation, bringing your foot down to the button and “mashing it” produces full power braking immediately.

Braking up front is via large, well cooled. inboard discs. Another thing is, when you mash on the button, the rear of the car will stay level, if not drop slightly because when the DS was introduced, it was built-in load sensing/brake proportioning, regardless of front/rear load balance.

The other thing about DS braking is that the champignon/mushroom pedal allows for quick foot movement from the accelerator pedal to the button. Unlike a conventional brake pedal where you lift your foot to the other pedal and then mash on it, on this you drop your foot off the gas pedal directly onto the button. Activating the brakes in a DS happens a lot faster than a conventional brake.

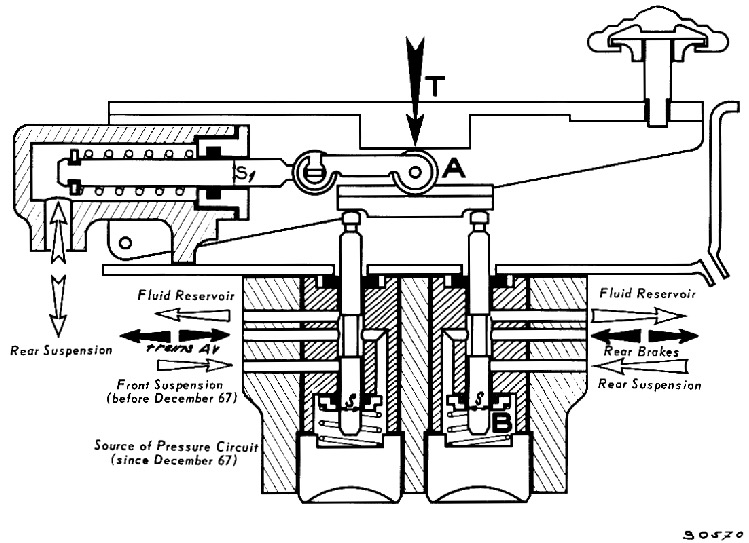

Underneath the mushroom knob is a split VALVE system, not a master cylinder type system – one tiny 1/4 in. diameter piston for front discs, another identical piston behind the front one, serving the rear brakes. Total travel from zero to full stop is – about 3/8 inch! The valves simply admit the stored high pressure in the system to the brakes. This sounds crazy, but it’s a true feedback proportioning system so your foot does get used to the gradation in force. Sheer genius!

To make it more brilliant, the mushroom knob pushes not directly against the two pistons, but on the CENTER of a teeter-totter plate which straddles both pistons. AND a tiny hydraulic piston forward of this twin hydraulic valve block pushes the TT plate forward/aft based on the pressure coming to the auxiliary piston from the rear suspension, whose height is affected by the trunk load. So, when a heavy load is in

And further to the brilliance of the design, as the rear suspension arms are very long, to give lots of soft wheel travel, when the rear weight is high and/or front brakes are pushed hard enough, the rear drums engage and rotational torque from them YANKS the rear end DOWN – it squats automatically, and counters any tendency to nosedive. In fact, if a DS doesn’t show the squatting rear under hard braking, a knowledgeable owner will know the rear brakes on a DOT 3 early car will have stuck rear cylinders, and you know you need to free them up with an overhaul.

It’s the tiny travel which throws people – literally – thru the windshield if you stomp on it! So – be GENTLE – this is NOT a vacuum-boosted system. There is 2500 psi of pressure, enough to operate a forklift, is under that mushroom knob!

I could go on and on. . . These are brilliantly, thoroughly engineered automobiles.

These button which pushes the slider valve had only come on the Pallas with BVH , if my memory serves me correctly.

I have one of these brake modulators as spares along with few other components for the LHM DS, but also have the LHS2 , that I had been collecting for testing project- on hold until I get other components to make it into a rig for either testing the pressures at various , I.e between components to see what pressure goes where , I.e using high pressure gauges between each of the components or for the troubleshooting purposes.

I would prefer this assembly , because the DS behaves differently upon applying the foot brake button.

As Ken put it, the actual assembly distributes pressure where it is most needed, via the pressure sensing, this assembly is very smart.

I think I have another write up somewhere, it’s used on the SM too.

To the best of my knowledge, one of the things that makes a “DS” a DS is the presence of the trolley valve as opposed to the ID type doseur valve. My 23 Pallas certainly had the trolley and it was a five speed, not a BVH.

Then there is the matter of the wagons for which the trolley valve was also included despite being an ID type. Given the huge load area of the Safaris and enormous loads they sometimes carried, perhaps it is not so surprising Citroën elected to fit them with the superior trolley type variable braking distribution.

The 1956 DS19 has two brake accumulators. One for the front, as all DS, ID breaks/familiales/shooting brakes, station wagons, and the SM. However, the ’56 ID19 rear suspension pressure went only to the proportioning trolley. Later DS sedans and ID wagons dispensed with the brake accumulator for the rear brakes. Both the proportioning trolley cylinder and the brake control valve for the rear brakes are supplied from the rear suspension.

The 19 brake rotors and the earlier 19/20/21/23 rotors are of a very hard cast iron that doesn’t wear. As these brakes sometimes made screeching and graunching noises, the rotors of later cars’ were of a softer cast iron that wears. After replacing the pads two or three times the discs are worn to a point that they are not thick enough to be refinished and must be replaced. This is a major job requiring the removal of the outer halves of the brake calipers, the front wheels, and the nuts holding the tripod joints and rotors. The drive shafts (les transmissions) are slid out far enough to remove and replace the rotors.

The early DS19 button was not a “mushroom.” It had little squish. Any bouncing of the foot on the rubber pad would cause grabbing of the brakes. The mushroom pad greatly reduces this effect.

When I had been driving DSs, IDs and SMs for several years, any time I drove any other vehicle I tended to get my shoe caught under the edge of the brake pedal.

“bringing your foot down to the button and “mashing it” produces full power braking immediately”

That can cause the brakes to lock up.

“Unlike a conventional brake pedal where you lift your foot to the other pedal and then mash on it, on this you drop your foot off the gas pedal directly onto the button.”

It’s not like you’re completely eliminating the upward motion. You still have to lift your foot of the throttle. Conventional pedals can also be adjusted if you want the brake to be in a lower position.

All in all an interesting and quirky system that’s not very necessary all things considered. No wonder they discontinued it in future models