Citroën’s Innovative Hydropneumatic Suspension — A Result of Adaptive Engineering

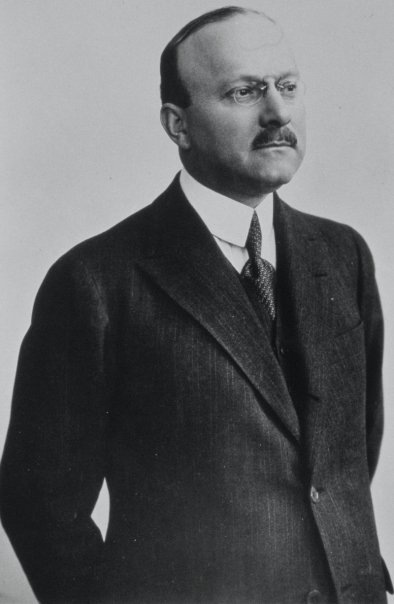

Citroën has been noted for its innovation since its inception. Even prior to the founding of the company in 1919, André Citroën recognized innovation, seeing the potential of double-helical gears and purchasing the patent for them in 1900, but it was really the combination of adaptation and innovation that was the formula for the company being distinct — a trait that Citroën continues to market to this day.

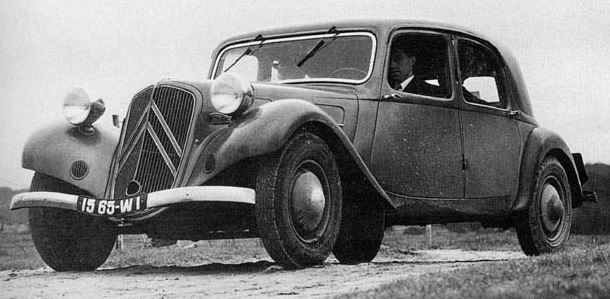

First of this combination for Citroën as a company was the adaptation of assembly-line mass production. André Citroën repurposed the munitions production he established during WWI to produce automobiles in an assembly-line manner that he emulated after seeing how Henry Ford was succeeding in the USA. André Citroën innovated again in 1934, by taking the potential he saw in Budd Automotive’s monocoque body construction and marrying it with front-wheel drive technology, doing both simultaneously for the first time in a mass-produced automobile. The result was the Traction Avant.

Though the Traction Avant was the last Citroën that André would have direct involvement with until bankruptcy forced him to cede his company to Michelin in 1934 (and his death in 1935), he instilled a legacy in the company that even by the measure of people today, critical that modern Citroëns have become mainstream and homogenous, carried on within Citroën, particularly with its engineers and managers, for 50 years!

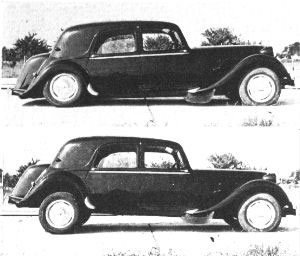

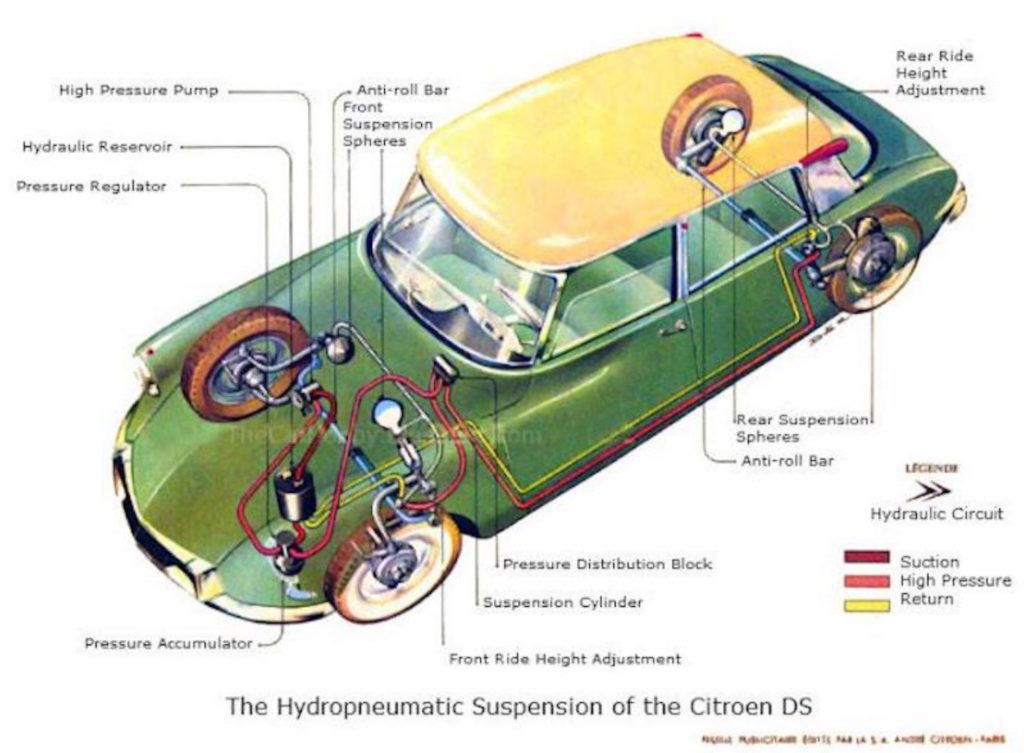

The most notable innovation Citroën is recognized for is hydropneumatic suspension, first introduced in the rear suspension of the 1955 Traction Avant 15/6H, as a “rolling testbed” to prove the technology, prior to showcasing full hydropneumatic suspension at the launch of the DS 19 in 1955.

Although Citroën touted the system as being a company innovation, Messier air suspensions shown in the 1920s were the precursors of the famous suspension of the DS.

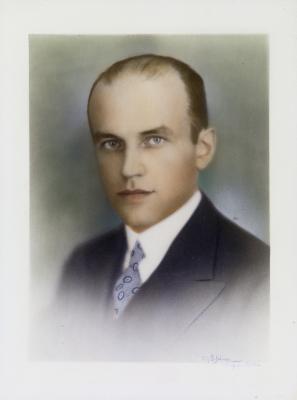

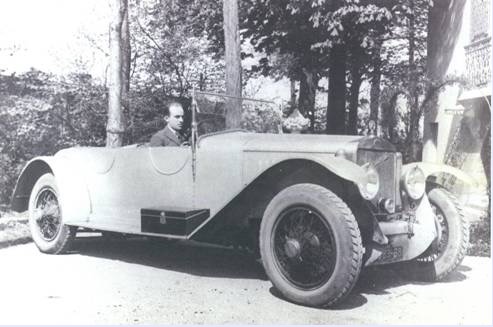

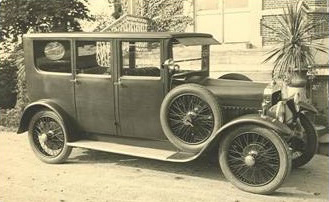

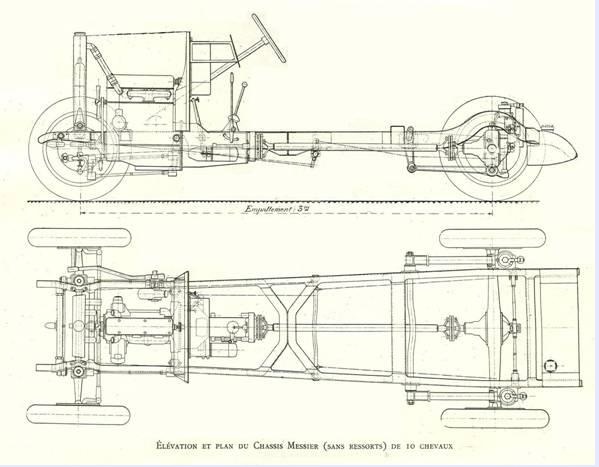

After having tested his “oleopneumatic without springs” suspensions on a Peugeot 201 in 1920, Georges Messier launched his own cars from 1925 with 4-cylinder engines (CIME) then 6 and 8 cylinders (Lycoming) in 1928. The factory was in Montrouge (Seine).

After having sold around 150 models (including many ambulances), he stopped automobile production in 1931 to focus on aeronautics, including landing gear for planes. (The company still exists, integrated into the Safran group with Bugatti and Hispano Suiza). He died prematurely in 1933 from a horse accident.

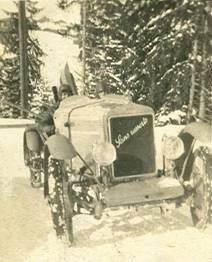

Messier automobiles participated in numerous competitions to assert the qualities of its suspensions between 1925 and 1928 and they often finished first, especially during events difficult on bad roads!

WWII played a significant role as Citroën’s engineers were intrigued by Messier’s accomplishment, and with production demand nearly completely suspended, could pause and reflect on how to hone both efficiency and innovation.

The 2CV was the first post-war example of this but in the background, a grander model was in the works.

In January 1942, Citroën CEO Pierre-Jules Boulanger assigned Paul Magès to the development department, to solve problems in the development of braking and suspension systems (including for the Citroën 2CV). Magès formal schooling was modest – he earned his National diploma (Brevet d’Etudes du Premier Cycle), a preparatory course for the Académie des Arts et Métiers in Marseille. At age 17, he sent his résumé to Citroën, one of the major automobile manufacturers in France, where he was hired to maintain equipment. In 1936 he became a technical draftsman and when becoming empowered by Boulanger, actively sought to challenge the conventional wisdom that a supple suspension system was incompatible with good handling.

While engineering the clever but simple spring compression system for the 2CV, Magès realized that to produce a car with both qualities, the solution must be a variable suspension, one that is very flexible at low speed, and stiff at high speed and load. Messier’s suspension showed promise for suppleness, but for variance at speed, it needed to be controlled. Experimentation by Magès led to the eventual development of hydropneumatic suspension, combining compressible gas in an enclosed chamber with non-compressible fluid, like the force multiplication used in hydraulic machinery. The heavier the load, the higher the gas pressure, so the suspension becomes more rigid.

Magès ultimately concluded that hydraulic fluid under pressure, delivered by an engine-driven accessory –- a hydraulic pump – was the best way to achieve the desired result. (Magès also developed DIRAVI speed-sensitive power steering, first used on the 1970 Citroën SM). Under Magès direction, it was now up to Citroën’s engineers how to manufacture the system at costs adapted to mass-production and achieve operational reliability.

The following description translated from Messier’s 1920s product brochure shows the technology Magès had knowledge of for hydropneumatic suspension development at Citroën:

The problem of suspension is the most delicate that the engineer encounters in the establishment of a chassis: many contradictory factors are involved; the suspension should be both soft, to ensure comfort at low speeds or with low load and also allow good handling at high speeds or when the car is loaded.

The metal springs created to ensure the suspension of horse-drawn vehicles circulating at low speed, and which in general have undergone only a few modifications to be applied to automobiles, no longer solve, except in a very imperfect way, the problem of the suspension, despite the use of various shock absorbers which only slightly alleviate their numerous drawbacks, tremors on the pavement, racket blows, etc.

In addition, with springs, the car only has passable suspension for a given load, usually when all the seats are occupied.

No spring suspension satisfies the following good suspension requirements:

- Automatic adjustment according to the load;

- Softness at all gaits;

- Good handling at high speeds;

- Complete elimination of the risk of breakage and wear.

The MESSIER air suspension perfectly solves the problem, it eliminates the metal springs which are replaced by four air suspension devices and provides vehicles with maximum comfort.

Air alone, in fact, is perfectly elastic; there is as much difference, from the point of view of smoothness, between a car with air suspension and a car with springs, as there is between a car assembled on tires and a car assembled on solid tires.

In addition, in the MESSIER air suspension, the softness is the same regardless of the load, because it automatically adapts to variations in the weight carried.

Each of the four devices consists mainly of a cylinder fixed to the chassis and in which moves a piston secured to the axle; a mattress of compressed air trapped in the bottom of the cylinder ensures the elasticity of the system; an auxiliary capacity increases the volume of the air on which the piston acts and provides a great softness of suspension, thus ensuring the progressive absorption of shocks even the most violent. A reduced section of the openings slows down the passage of air and thus eliminates racket blows.

A very simple distribution system ensures automatic adjustment according to the load and compensation for losses; the power comes from a central tank where the pressure is maintained by a small pump controlled by the motor; a return line allows air circulation in a closed circuit; this air entraining a certain amount of oil, thus ensures lubrication and complete sealing of all the organs.

The experience of many cars, some of which have covered more than 100,000 kilometers, shows that there is practically no wear and tear and that well-established pipelines cannot cause any trouble.

SAFETY - The experience of braking compressed air on railways shows, moreover, that this pressurized fluid adapts perfectly to the conditions of installation on vehicles.

DURATION - We know that spring cars, after a certain route, arrive at a period in which all the chassis organs being tired by vibrations and vibrations, repairs follow one another.

This phenomenon is well known to motorists and has given rise to the term "Repair Period".

With the MESSIER air suspension, on the contrary, it has been observed in practice that the car does not age.

This advantage alone would more than offset the slight price increase caused by the air suspension.

(Extracted from the “Automobiles MESSIER” brochures – Models 1928, and Models 1929).

You can view one of the few surviving Messier cars at the Charbonneaux Automobile Museum in Reims, France.

Terrific article – I’ve always wondered how Paul Mages came up with the hydropneumatic suspension – I thought he had seen the long stroke landing gears of planes as the source of the idea, as aren’t they oleostruts with air cylinders on top?

Never heard of Messier before, but a couple yrs ago during a road rally with a Michigan car group, we visited a fellow who restored Civil war cannons and later ones. He showed us one cannon which did not have to be positioned and aimed again after every shot. It had a hydro-pneumatic recoll system which absorbed the shock of the barrel recoiling on the carriage, and being returned slowly to original aimed position by an air cylinder. It was built in 1897! And it was French! So the principle was known to the French engineers yrs before even Mages came along. How’s that for going back in time? Thanks for posting this article – now I know how it all started.

Ken Nelson

It’s not a car, it’s a lifestyle of great innovation. Thank you for the informative article.