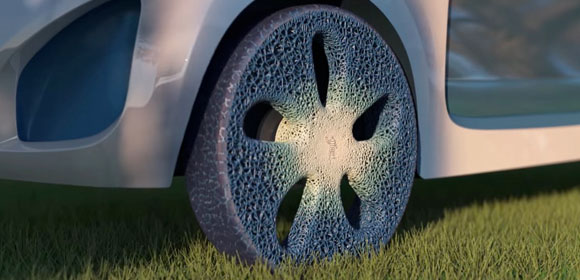

Michelin presented its future concept of adapting 3D printing technology to tire production at the Movin’on Show in Montreal earlier this month. Officially called VISION, it is a tire and integrated wheel. Unlike traditional tires with rims it does not contain any air, and is designed to last as long as the vehicle. Made from recycled materials (and recyclable at the end if its life) the tire consists of a honeycomb structure inspired by natural models, as well as a tread offering the same performance as a traditional tire.

VISION relies on an interior architecture capable of supporting the vehicle, ensuring the solidity of the wheel and thus guaranteeing both comfort and safety. VISION can neither explode nor blowout.

This tread can be modified (effectively resurfaced) at will via 3D printing technology. Michelin envisions having 3D tire printing stations that vehicles can can simply pull up to and have fresh tire tread re-applied. As such tread can be applied for specific conditions (rain, ice, snow etc…) and thanks to communication with the vehicle about weather and road conditions, warn or advise of the best “configuration” to choose according to the type of route.

A “smart” wheel, and more importantly, environmentally friendly: it was designed by Michelin engineers and technicians to conform to the company’s new branding known as “Strategy 4R” (Reduce, Reuse, Renew and Recycle).

See the concept video here: https://www.youtube.com/watch?v=Tyc4Apyk2Rc

Please don’t fool yourselves that it does not contain any Air in this tire!

It have air pockets into the mix, just like a sponge.

With a solid mass of rubber without any air whatsoever, the vehicle will slide away, especially on ice and snow.

From memory , Michelins had a tire experiment which also didn’t contain any Air, bit it’s clever design had spokes, If it were produced, it’s name I believe was ‘TWEEL’, correct me if I am wrong.

I stand to be corrected anytime.

Cheers