Paul Magès, A New Website, And His Antigite System

By the CItroënvie editorial staff….

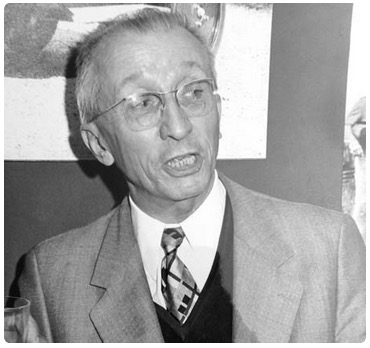

Paul Magès is the father of Citroën’s hydraulic systems. He was a brilliant inventor, responsible for the development of high-pressure hydraulics for various design solutions at Citroën.

A website honoring Paul Magès has been created by members of his family (Michel and Igor Magès). The website includes scans of his hand-written notes about various technical subjects as well as rarely seen photos.

One set of writings shown on the website are his thoughts about eliminating body roll of a car during cornering. This capability is referred to by the term, Anti-roulis or Antigîte. (Apparently, the term gîte is not just a French vacation rental property, but is also a French nautical term referring to a boat that is listing to one side or the other.)

Paul Magès was studying anti-roll systems as far back as the 1940’s. One of his early ideas involved the use of a pendulum to operate a system to control body roll. Some of his concepts included electrical control systems and others were hydro-mechanical in nature. But it seems that these early ideas were at least partially shelved until the DS came along. Citroënet reports that six testbed DS’s were equipped with various versions of anti-roll systems, the earliest of which occurred in 1955.

Below is the famous photo showing one of Citroën’s test vehicles in a corner, with and without Paul Magès’ anti-roll system activated.

Citroën found that the system increased cornering forces by 30% and immensely reduced tire wear by keeping the tire’s footprint in better contact with the ground. It was a success. But as we shall see, it was not yet suitable for production due to cost, complexity, and the need for further refinement.

We have attempted to translate Paul Magès 1961 writings about anti-roll, but it was a bit of a challenge due to the legibility of his hand writing in combination with our sub-optimal translation skills. Nevertheless, we included some of his thoughts below (edited, hitting just the highlights):

“…Experience shows that maximum comfort in motor vehicles can be achieved by increasing the flexibility of the suspension systems. (Citroën’s) suspensions are equipped with automatic (height) correction, which increases the suspension’s flexibility. Additional elastic devices limit the vehicle’s roll during cornering, from the action of centrifugal force. These anti-roll devices consist of a metal bar acting in torsion, called “anti-roll bars” or “stabilization bars.” Even before considering (automatic) stabilization devices, auto designers had a goal of keeping the vehicle parallel to the ground during cornering.

Given the forces required, the reaction that would be necessary (to control roll) would be difficult to be practically achieved. This firmly supports (that it would be possible to design) an active system triggered by a pendulum or by the inclination of the vehicle itself.

A motor vehicle equipped with the active anti-roll system discussed in our patent includes stabilizer bars connected to the arms or links of the wheels, with hydraulically controlled levers to cause movement in relation to the suspension’s arms or links.

In a turn, the fluid pressure allows the stabilizer bars to be stretched to create a torque opposite to the steering wheel input or of the centrifugal force. The fluid pressure adjustment is made, more or less quickly, depending on the intensity of the signal and is automatically stopped by a valve at the moment when the desired inclination is reached. The opening of the valves and the pressure in the cylinders are controlled by the steering effort, made by the driver. This can be accomplished in various ways, but it is practical to directly use the pressure in the power steering system for the anticipated direction. Indeed, at the moment when the driver acts on the steering wheel, a pressure is generated in the circuit, either right or left, depending on the direction of travel and the value of the actual pressure. This pressure is a function of the driver’s action on the steering wheel and by the centrifugal force as soon as the car actually starts to lean. This pressure serves as a “signal” and commands the anti-roll system.

The control of anti-roll by the steering force serves the condition defined above. Indeed, there is an offset between the moment when the steering force is first applied and the moment when the steering force becomes effective. At the moment when the car is actually undergoing a centrifugal force, the offset is used to control the opening of the tilting valves, as mentioned above. These valves are activated by the pressure of the power steering, which functions as a measure of the driver’s effort. The realization of these valves is done such that it is a function of the pressure of the power steering, which makes a tilt correction to match the action of the steering wheel by the driver.

The pressure in the cylinders connected to the anti-roll bars is adjusted at the moment when the inward inclination has reached the correct value, a value always identical regardless of the turn and speed, a value mechanically controlled by the relative repositioning of the right and left wheels. The car remains flat as long as the steering pressure is maintained, and this pressure is released when the steering is relaxed, allowing the car to regain a normal attitude.The front and rear stabilizer links are dynamically connected, such that the first force is sent simultaneously to the front and rear. The front and rear anti-roll bar torques are therefore always in a well-defined relationship, regardless of the ground surface on which the vehicle is traveling…”

Confused? We are as well… But after reading this many times, our simplified take-away is that his anti-roll system uses the pressure in the power steering system to initiate a tilting action on the inboard wheels using hydraulic cylinders acting on the suspension arms. And then by measuring the actual tilt of the car, the anti-roll system adjusts the valving to hold the car in its new flat attitude. Once the pressure in the power steering (left or right) is released, the anti-roll system becomes inactive and the car returns to its relaxed (un-corrected) attitude.

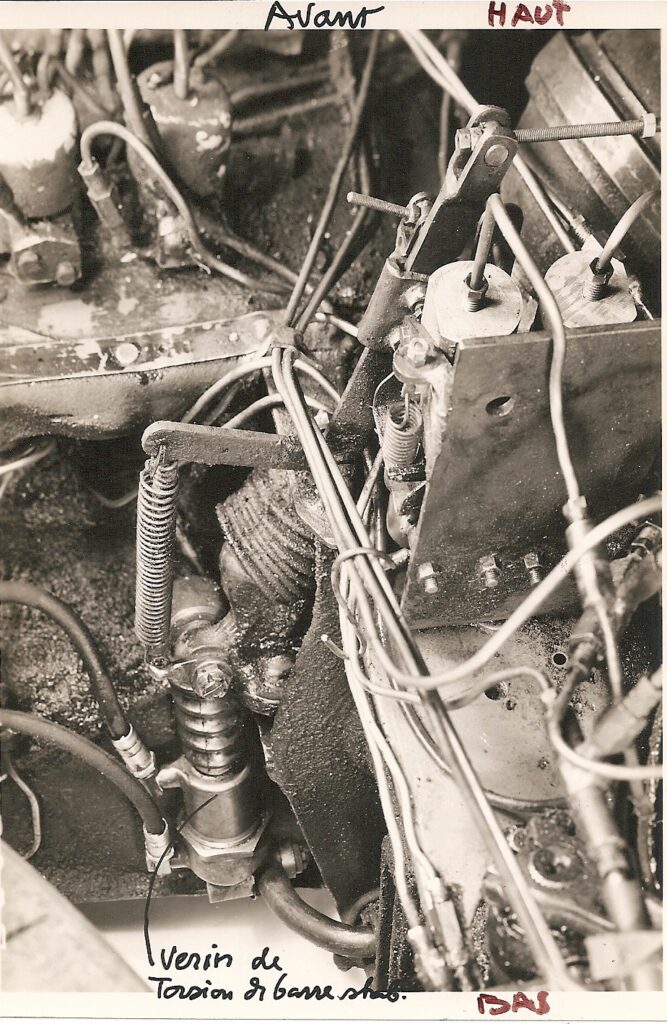

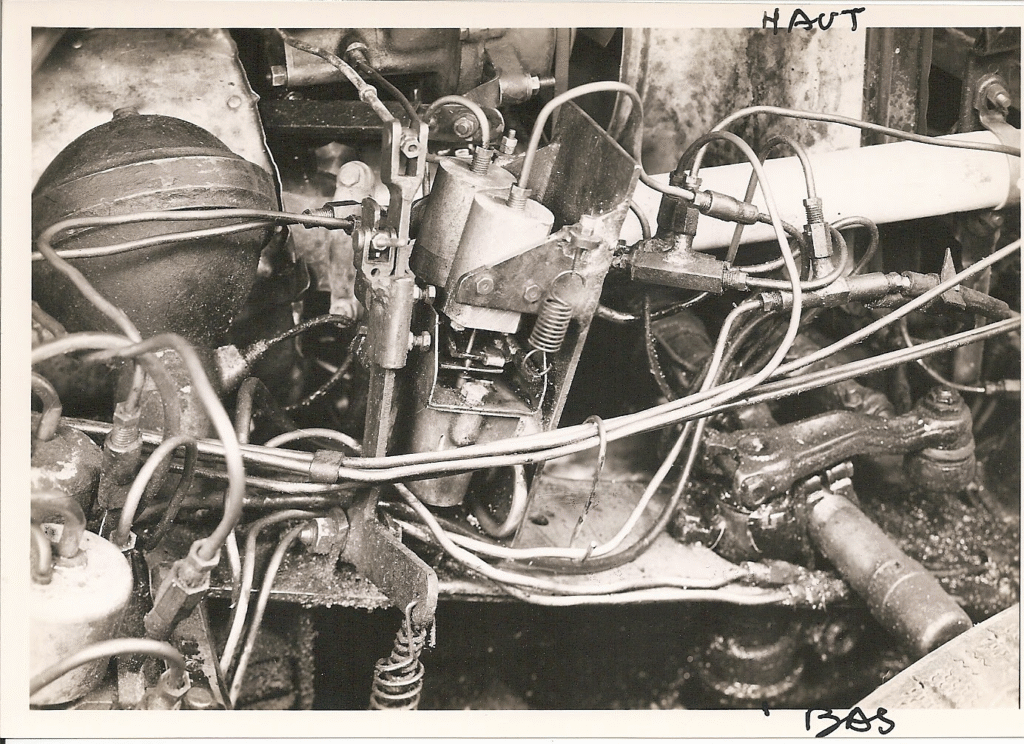

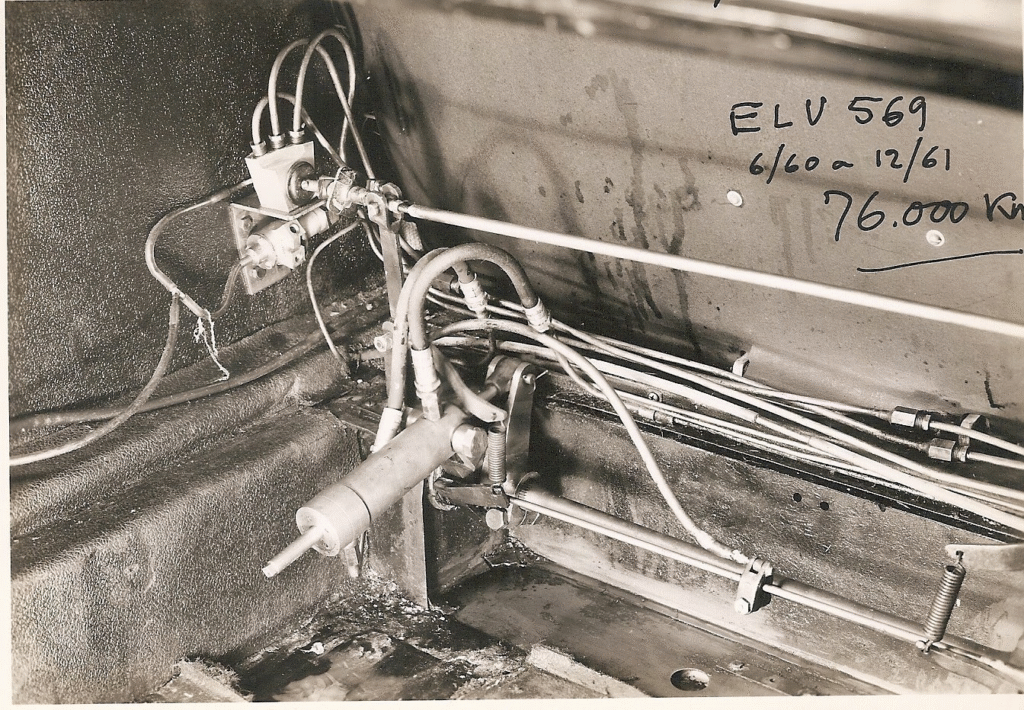

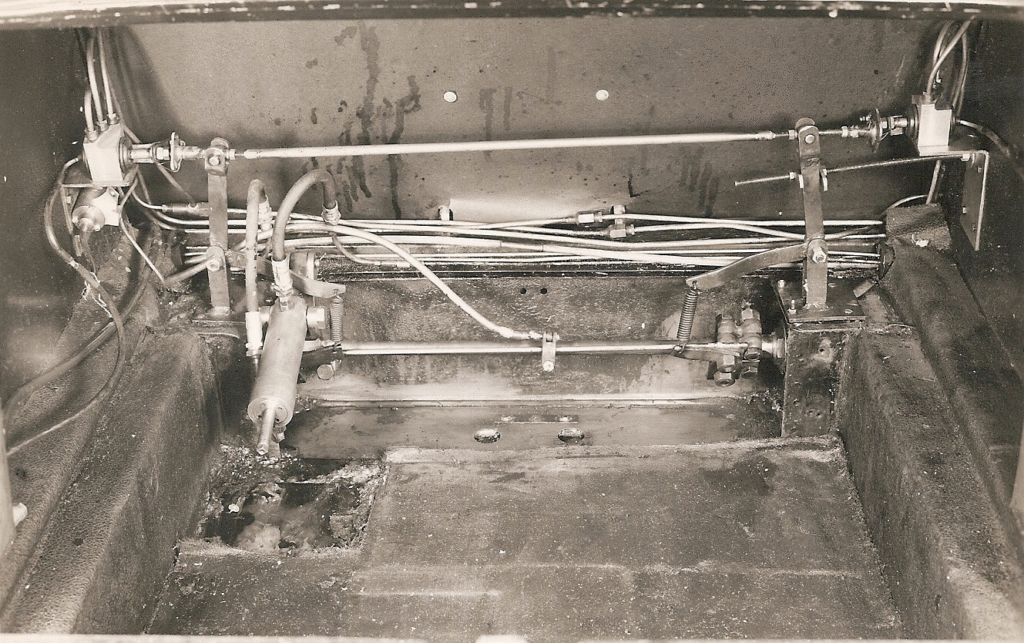

The website includes some photos that I have not seen before showing the intricacies of Paul Magès’ anti-roll system. Looking at these photos suggests that the implementation was not trivial. As amazing as the concept is in theory and in test, we can see why the project was not commercialized, at least not until electronics allowed a more straightforward implementation. As we all know, Citroën did return to active roll control, but it was not until the mid-1990’s with the Xantia Activa. Paul Magès was still alive when his idea from 50 years earlier came to fruition and we hope he was able to experience it.

You might want to peruse the PaulMages.com website. The site creators are requesting donations so they can continue to scan and publish more of Paul Magès files. We donated and are looking forward to what else they share with us!

Jerry Hathaway developed a central sphere for the SM front suspension to reduce roll. Did anyone out there ever have it installed?

There was something that Jerry Hathaway of sm world did that supposedly helped some of the roll on SMs ; anything about that that’s related to this and I thought he did put it on a car or two so anything doable now?

I know he put it on one of his cars and I was going to try it, but I never perused it. He did tell me that it helped and I know it was a 3rd sphere that somehow restricted the fronts from having a free crossover. That probably reduced the dive on the outside sphere. It may have been an adaptation of something Citroen used on the XM.