By L. Lewis….

Following up to my previous story about this 1937 11BL, I thought that I ought to remove the cylinder head after doing a compression test. The readings were: number one is 90 psi which sounds reasonable. #2 is 140 psi which I find odd. Then 3 and 4 both of which show zero! So, the head comes off and what do I find? Bent pushrods from 3 of the intake valves. Not a good sign. On removing the head and with the block drain plug being unremovable, the head comes off and water enters the cylinders and sump.

Mopping that up and a further look at the cylinders shows reasonable wear with no ridge at the top that I could detect but down in the tappets there was metal bits that I removed with a magnet. That isn’t good. Probing the magnet into the water jacket I picked up a fair bit of metal bits that stuck to the magnet. So the engine is coming out to resolve all these unexpected bumps and hiccups. It’s the right thing to do.

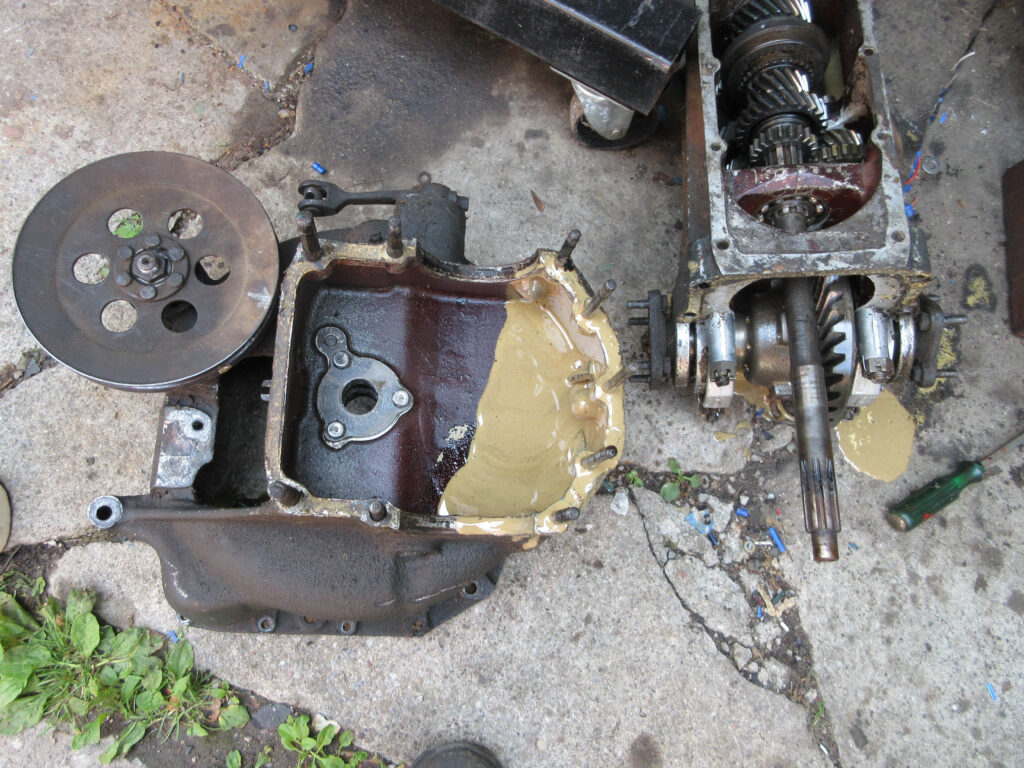

Doing the preliminary work to remove the engine, I removed the top of the gearbox. Found that 2nd gear moves fore-and-aft about a quarter of an inch. Not good. The gearbox oil was not pretty; a light brown colour that looked like a watery chocolate syrup that you really should not be putting on your ice cream. I can only imagine at this point what the oil in the sump looks like, not to mention the crud that accumulates in the crankshaft throws. Crust inside the sump and everywhere else.

Disconnecting everything, I find that the clutch cable adjusts from the front where on the ’49 its adjusted from the rear which is an improvement. Working in my crummy garage means trying to move an engine hoist around on a cracked concrete floor. Lots of fun, for sure. But once the engine is out it will sit in a cradle made from wood and a furniture dolly which isn’t so bad. Turning the engine over to remove the crank will mean an unholy mess of oil and sludge that didn’t drain from the sump. It’s always something.

The engine is out now and it was less of a fight than I expected since the inner cardans retracted a fair distance. More things that I found are that the top cover of the gearbox is held on with bolts and not the proper studs. There are small cracks around one of the bolt holes but I don’t see that as being a problem. Looking at the steering rack, I see there are no gaiters on it, neither leather nor rubber. Nothing. The entire engine bay is looking rather crusty so that will need to be cleaned up and painted. I had the front crossmember cut so to make removing the fan belt less of a trauma than it normally would be.

Removing the tappets, one had its top edge all chewed to bits so this must have been caused by a bent pushrod. Did this car actually run? If it did it must have run pretty poorly. The cylinders will come out and be sandblasted and honed and new piston rings all round. Scraping all the scale out of the block will be a fun tedious job. Beer will be required for such mindless work. I will be adding an aftermarket oil filter, a Frantz filter that uses a roll of toilet paper for its element. They work well as I’ve had one on my 11B since 1988. A Roger Williams oil pump and all will be well. There is an oil pressure gauge (in English, original?) that is fed from a fitting on the side of the oil gallery adjacent to the rear plug. That will be removed and tapped for a fitting to feed the oil filter and the return for it will go back to the oil pan. No, not a full-flow but better than factory equipment.

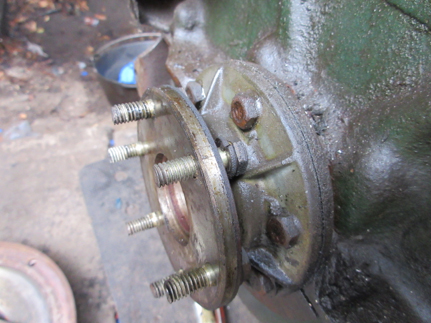

Removing the gearbox and clutch shows that there is a bit of rust on the flywheel and two of the bolts holding the flywheel to the crank had come loose making removing the flywheel a fun thing. But it came off and there will be Loctite on the bolts when the time comes.

Removing the bell housing from the gearbox resulted in a pool of light-brown slime on the garage floor. Nasty stuff.

The gears all look OK but the end float of 2nd gear will be dealt with by replacing the upper shaft with the one from the gearbox of my 11B which blew apart on my way to La Ferté Vidame 4 years ago (when I shipped it over to Europe for the event). The shaft is unbent so it’s usable and the end float of 2nd gear is spot-on. I will use the synchro hub from that box as well since I know it’s in good shape.

All of the local clutch rebuilders are now out of business so it must go to Ottawa where the last rebuilder in the province is located. They are experienced in classics so no worries there. It’s just a pain having to send it there instead of just taking it somewhere local. Oh well.