By L. Lewis….

Taking the oil pan off revealed about an inch and a half of solid slimy black sludge that had to be scraped out with a paint scraper. Nasty stuff which was as thick as mayonnaise.

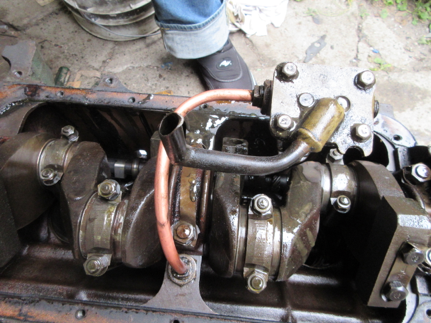

Washed the pan out with gasoline, then brought it to the machine shop where he will hammer out the dents that obviously resulted from an idiot jacking the car up. After being sandblasted, it was full of holes so that had to be dealt with. The oil pump has no pickup screen of its own, only a pickup tube that inserts through a hole in the screen fitted to the sump. I understand that is the way of the early cars. Either way, it was not pleasant cleaning this mess.

I removed the oil pump and sent it to Roger William’s for a rebuild and upgrade. I collected it when I was over there in September.

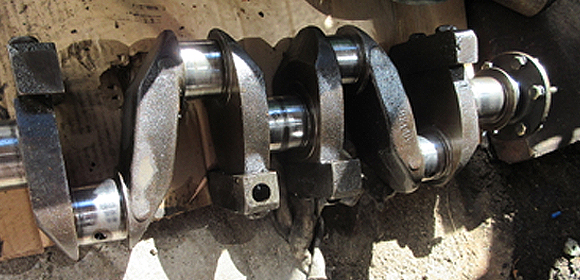

The crankshaft and connecting rod bearings all look reasonably OK to me but I’m not a machinist. I see nothing wrong except normal wear so that will be addressed. From using my plastic vernier calipers, as far as I can tell the crank has never been ground so we will see about that. How wrong I was about that!

The pistons came out without too much trouble but the muddy sludge on number 3 is a mystery. Water got into the cylinder, I suppose. All the others look reasonably OK. The pistons and original sleeves are now at the machinist for cleaning and honing so hopefully they won’t need to be replaced. Removing the piston rings, I managed to break every one except for two. The pistons did clean up fairly well. And with new rings and rods will be OK.

It’s now late October and I’m back home. My suitcase was loaded with parts but wasn’t overweight. The clutch arrived in a very heavy box. Soon it will be too damn cold to work on it. I was hoping to get the engine and gearbox back in the car by mid-October, but that didn’t happen. It’s not going happen until next spring.

Further developments show that the crank is at 49 mm on the main bearings and 47.22 on the connecting rod bearings. The rod bearings can be sorted out easily but the mains might need further work such as building up the journals by welding and then turning them to the proper size. 49 mm is the lowest undersize so the crank can’t be ground as it is but I was told later that it can be polished and used.

The machine shop guy said that two cylinders sleeves are rusted in vital spots and should be replaced so they were ordered. Further on, my machine shop guy said that the other two sleeves are worn in a tapered fashion and that the piston rings are at their outer limits so two more sleeves arrived last week. At the time of this writing, all of the sleeves are in the hands of the machinist so it’s a matter of waiting, again.

The gearbox went back together without much trouble and it’s now at the machinist who will set up the differential which is not something that I can do as well as a professional. I know my limitations. The clutch and flywheel are now back home and are ready to install. Here it’s late October and the weather is getting cold so this little project will have to lay over until spring which in Canada comes around late April.