Here are some pics of the work on a DS that Rob Murdock in Waynesville, NC has been doing for over the last year. So far, he has put in 500 hours performing the following:

- Complete removal of ALL Ziebart undercoating from frame inside and out

- Weld new metal panels on the frame

- Complete overhaul of all hydraulic components to include revision from LHS to LHM

- Change exhaust header from single to double

- Removal of cylinder head

- Install 8 new lifters (cam looked fine)

- Install new valve seals

- Install one new exhaust valve (as it was bent)

- Milling of head

- New head gasket

- New Valeo starter

- New alternator with internal voltage regulator

- New suspension boots front and rear

- All new drive shaft boots

- Replaced the stub axle nuts with more heavy duty nuts and replaced one entire stub axle

- New gas tank

The above is just a sampling of work done thus far.

Rob notes that; “The entire frame has been stripped of Ziebart and old fuzzy insulation on the inside as well. I believe there was a thick coating of Ziebart in the cabin too. At any rate all but about 20% of this is done, primed and repainted with an epoxy time permanent paint. All done by hand and incidentally, and this black paint (similar but I think better to POR-15) will not come off of your hands thus gloves are a necessity.”

Ziebart is particularly difficult to fully remove. Rob de-Ziebarted an SM many years ago and recalls what a pain that was. (Here in Canada, Ziebart proved to be the kiss of death to any cars that were done. The stuff would dry out and crack, then salty water from the tons of salt that was applied to winter roads mixed with the snow to became slush, and crept in the Ziebart cracks and under it, creating a haven for the rust gremlins to do their work. Nasty!!!)

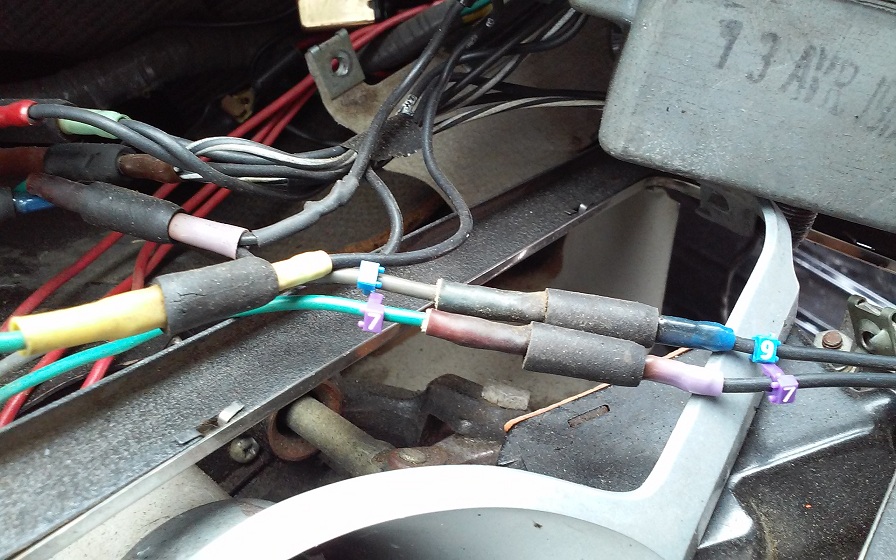

In the wiring there was much corrosion — almost to the point of a fire hazard!

He did not rebuild the steering rack, high-pressure pump or pressure regulator. He did install new accordion boots and other new steering components external to the rack though. (Installation of the boots is real fun by yourself as you probably already know!)

Rob also rebuilt the brake calipers, suspension cylinders, height correctors, brake pressure unit and priority valve. He had an extra LHM steering rack so he did a rebuild on it and has the original LHS rack for a rebuild if anyone is interested.

Rob and a friend made a new tool to disassemble the suspension spheres. As Rob wanted to use the rebuildable type suspension spheres rather than the “pineapple type” (as some refer to them) that cannot be opened to replace the diaphragms, he and a friend made a new tool to disassemble the spheres.

Rob also installed a DS heat shield behind the engine, (not easy, but easier with the head off). His goal is complete silence inside the cabin and is anxious to see how successful he will be on that issue!

Of course new carpets and all the other ancillary items necessary for completion of the interior are also on the agenda.

As found

Wiring corrosion – main harness

Passenger side frame patch outside grinding.

Passenger side frame inside patch grinding.

Passenger side frame horn trial fit cover III.

Passenger side frame horn cover trial fit IV.

Passenger side frame horn cover trial fit V.

Driver’s side frame horn bottom cover fabrication I.

Frame – horn fabrication II.

Frame – horn bottom cover fabrication III

Driver’s side frame horn bottom cover fabrication IV.

Driver’s side frame horn bottom cover fabrication V.

New sphere clamp from MR I

Sphere clamp MR II

Sphere clamp MR III

Sphere clamp MR IV

Passenger side wiring I

Cable marking wiring in dash

Starter Solenoid Wiring

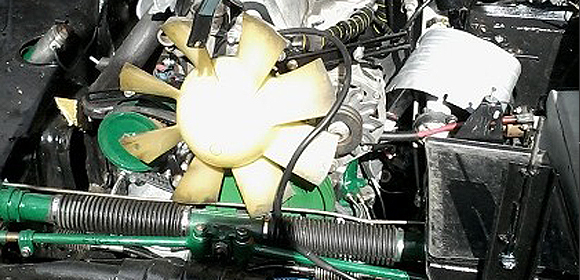

Engine Trans – April 1, 2021

Engine Trans – April 1, 2021

Rob’s Citroën habit started about 1963 when his dad first bought an ID19 and conscripted Rob and his ten year-old twin brother to work on it in the cold Missouri winters. Rob says that; “It was the best thing his dad could have ever done for us!”

Rob’s intuition about Citroëns continued and over the last fifty years he ventures to say that he and his brother have had at least 30 DS’s and or SM’s. The SM’s were fewer (Rob thinks the total was five) and all were sold at that time as they had small children and just could not afford to continue with them.

Rob has spent about 20 years in the aviation business as a commercial pilot and sales agent for all types of general aviation aircraft. He has also spent 48 years as an avid musician and considers that the preponderance and focus of his career. Both of these paths, and his love of Citroëns, have been the primary motivators in his life.

Aside from working on this DS, Rob offers to help other Citroën owners in the North Carolina area keep their cars in good repair. You can reach Rob at: murdockjazz@gmail.com.

Update from Rob — Sept 1, 2021:

I just took inventory of the passenger side front floorboard frame repair and the drivers side floorboard repair. I did most but not all of the repair on the passenger side and counted up 52 hours. Right now we are a total of 27 hours on the drivers side X 2 or 54 hours total as both Johnnie (my expert welder) and I both were on this constantly. It takes less time with two but by myself it could have easily consumed 50 hours.

Outside cover at jackpoint

Gusset drivers side III

gusset drivers side II

Gusset drivers side I

Gusset in place and welded

We are almost done and this type of work. Its ALWAYS more than anyone thinks!

I’m sure you have seen this type of repair before but I didn’t know it would be this extensive or time consuming. So just a word to the wise for anyone buying a car. This frame rust was not known by the previous owner but I did suspect it and made it my business to uncover.

This is the kind of dedication to a project that yields positive results. Obviously, the spirit with which a job like this is undertaken can be an inspiration to others.

I am delighted that this car, actually a 1968 ID19 Grande Route, has landed in such talented hands. I bought her in 1997 from a guy in Whitewater, Wisconsin. The car was brought up from Texas and sat in dry storage for over 20 years. It was bought new by his father, who sold Cords and Essexes and was passionate about front drive. It has a unique air conditioning system. The battery was moved to the opposite side to accommodate the air conditioning pump mount, which is run off of the hydraulic pump, not the water pump as we commonly see. Rather than a Coolaire system, it has a Mark IV, more compact and better made. The longitudinally mounted condenser is attached to the air intake and has a bend in the middle. The alternator was then moved to the left side of the engine and voltage regulator relocated as well. Amongst the restoration work I did was a reupholstery job done in English wool, as the original fabric was unattainable at the time.

Notice, the following was written by this car’s 3rd owner, Mark Bardenwerper, at the request of its 4th owner, Richard Griffin. Mr. Murdock is the car’s 5th owner.

BEGINS:

Here’s a brief history of the D, or at least how it was told me. You will have to fill in the of the first owner. It is in the owner’s manual. Also the car was purchased in San Benito Texas and the name of the dealer is also in there, actually in the warranty booklet. So here goes. (Note: those books, and the ownership information they contain, are still with the car – Richard).

The first owner of the car was a retired car dealer. He sold Cords and Esssexes. He missed the front drive found in his Cords and at the time he bought his first D in 1966, they were the only car sold in the US that had it. That car got wrecked. I think there is a bit of arithmetic on a page in of the manuals you have that shows the prices of repair parts.

Rather than fix that one, he bought the one you have now. He drove it for a while, perhaps 3 or 4 years. The car has a Mexican “Tourista” sticker in the windshield from 1972, the last year he drove it. (That sticker was made to last – it’s still looking good on the windshield – Richard).His son-in-law, “Red” Hemlock, lived in Whitewater, Wisconsin. When he could no longer drive it, he gave it to Red and Red drove it back to Wisconsin and drove it very little. When he built a split level A Frame house near Whitewater Lake, he had a garage door installed on one end. He drove the car in and parked it in a back corner, were it sat for the next 23 years. It became covered with filth and lumber scraps and whatever and soon it could not bee seen beneath the pile. I was in that basement at one time and could not see the car!

I was an auto mechanic working at a shop in Whitewater starting in 1981 and I worked there until 1993, when I quit to go back to college. While there, Red was a frequent customer and we got to be good friends.

Additionally, I knew his son, Tim and in the late 80’s, when I was going through my divorce, he rented a room from me for a time. They both told me of this “Sitt roennn” that one day was going to materialize at my shop where I was to “give it a tuneup, I am sure that is all it needs”.

Well I was there for 12 years and it never materialized.

I left for college in 1993 and graduated in 1996. I then moved to Oshkosh. While there, Red retired from his home repair business and sold his house on Whitewater Lake to the Wisconsin Department of Natural Resources, who tore the building down and reverted the land back to the wild. The car was hauled down to my old shop in Whitewater where it sat outside through part of a winter. Early in the spring of 1997, I was driving by the shop and spotted the car. I pulled in and asked what was going on with the car. Rick, the boss’s son said, “Get it the Hell out of here! We don’t want to touch it!”

I was absolutely filthy, and had a slight truck tire crease up the driver’s side, but otherwise and complete and solid as could be, having never been driven in snow. I had never even sat in one before and had only seen one perhaps once in my dim memory. But when I puled behind the wheel and looked out over that long sloping hood, looking through that filthy windshield, I knew I had to have her and rescue her from an uncertain future. The car wreaked of mice and the seats, though not faded or worn, had clearly been used for nesting material. She was more mouse hotel than car at that point.

I got Red’s number and asked him if he would sell it to me. He said he had one guy looking at it already and he was coming back, so he gave me a rather high price. I told him there was no way I could afford it and told him I could only give him $2500 for it. I promised him that I would give him a ride in it as soon as I got it running. He called me back a day later and said “yes”.

Within a few days, I had the car on a 2 wheel dolly on its way to Oshkosh. As I cleaned and cleaned, I began to realize just how pristine this car was. Having been in a heated dry basement, it was spared the ravages of rust, repeated attacks on interior chrome by condensation, or sun damage to rubber parts. In short, it had enjoyed a nearly perfect hibernation, save the mouse damage. The first time it ran was actually quite dramatic. It still held fluid and of course, in my haste to get it running, I did not hot change it. So, after having the gas tank cleaned and a new battery installed, the car fired right up and started hesitantly to rise off the ground. The rear went up about halfway, when I heard a loud “bang” and she dropped like a rock, a pool of fluid spreading under it. That was when the books and the wallet came out. It wasn’t to rise again for nearly a year.

The first project was to get it to hold water. The upper radiator hose had rotted off and the antifreeze had hardened into a white concrete like substance in the openings in the block on up, so I had to replace the head, the water pump and spacer and the intake manifold. Getting all of the spheres and the pressure regulator rebuilt, the hydraulic tank flushed, and that nasty regulator return hose replaced that blew in the first place from excessive back pressure, the car rose at the first attempt. So confident was I that I had already bought plates for it. At the time, I was working in a Ford garage. The guy who rebuilt transmissions at the time, Dean and I drove it on a rally. The car went 50 miles without a problem.

Since then I have not gone through a year without completing some major project, each aimed at making the car more reliable and closer to like new. The paint and interior came much later. Being tight on the money, I did what I could as opportunities presented themselves. The paint job was done in exchange for an engine swap job on a 1968 Firebird. The seats, in English wool to match the texture and color of the original, was done in exchange for a new entrance awning and some roof work on the upholsterer’s shop outbuildings. I picked Bleu Camargue for the body and Blanc Meije for the roof to replace the sombre Gris Kandahar. They are Citroen colors from a few years later, but as I told the bodyman, I wanted the car to look like a cloud on a clear sky. And it does!

Here’s part of the story of this car, written by owner #3, Mark Bardenwerper:

BEGINS

A brief history of the D, or at least how it was told me. You will have to fill in the name of the first owner. It is in the owner’s manual. Also the car was purchased in San Benito Texas and the name of the dealer is also in there, actually in the warranty booklet. So here goes. (Those manuals are still with the car). Rob Murdock is the 5th owner of the car and I, Richard Griffin, was the 4th.

The first owner of the car was a retired car dealer. He sold Cords and Esssexes. He missed the front drive found in his Cords and at the time he bought his first D in 1966, they were the only car sold in the US that had it. That car got wrecked. I think there is a bit of arithmetic on a page in of the manuals you have that shows the prices of repair parts.

Rather than fix that one, he bought the one you have now. He drove it for a while, perhaps 3 or 4 years. The car has a Mexican “Tourista” sticker in the windshield from 1972, the last year he drove it. (Sticker is still there!) His son-in-law, “Red” Hemlock, lived in Whitewater, Wisconsin. When he could no longer drive it, he gave it to Red and Red drove it back to Wisconsin and drove it very little. When he built a split level A Frame house near Whitewater Lake, he had a garage door installed on one end. He drove the car in and parked it in a back corner, were it sat for the next 23 years. It became covered with filth and lumber scraps and whatever and soon it could not bee seen beneath the pile. I was in that basement at one time and could not see the car!

I was an auto mechanic working at a shop in Whitewater starting in 1981 and I worked there until 1993, when I quit to go back to college. While there, Red was a frequent customer and we got to be good friends.

Additionally, I knew his son, Tim and in the late 80’s, when I was going through my divorce, he rented a room from me for a time. They both told me of this “Sitt roennn” that one day was going to materialize at my shop where I was to “give it a tuneup, I am sure that is all it needs”.

Well I was there for 12 years and it never materialized.

I left for college in 1993 and graduated in 1996. I then moved to Oshkosh. While there, Red retired from his home repair business and sold his house on Whitewater Lake to the Wisconsin Department of Natural Resources, who tore the building down and reverted the land back to the wild. The car was hauled down to my old shop in Whitewater where it sat outside through part of a winter. Early in the spring of 1997, I was driving by the shop and spotted the car. I pulled in and asked what was going on with the car. Rick, the boss’s son said, “Get it the Hell out of here! We don’t want to touch it!”

I was absolutely filthy, and had a slight truck tire crease up the driver’s side, but otherwise and complete and solid as could be, having never been driven in snow. I had never even sat in one before and had only seen one perhaps once in my dim memory. But when I puled behind the wheel and looked out over that long sloping hood, looking through that filthy windshield, I knew I had to have her and rescue her from an uncertain future. The car wreaked of mice and the seats, though not faded or worn, had clearly been used for nesting material. She was more mouse hotel than car at that point.

I got Red’s number and asked him if he would sell it to me. He said he had one guy looking at it already and he was coming back, so he gave me a rather high price. I told him there was no way I could afford it and told him I could only give him $2500 for it. I promised him that I would give him a ride in it as soon as I got it running. He called me back a day later and said “yes”.

Within a few days, I had the car on a 2 wheel dolly on its way to Oshkosh. As I cleaned and cleaned, I began to realize just how pristine this car was. Having been in a heated dry basement, it was spared the ravages of rust, repeated attacks on interior chrome by condensation, or sun damage to rubber parts. In short, it had enjoyed a nearly perfect hibernation, save the mouse damage. The first time it ran was actually quite dramatic. It still held fluid and of course, in my haste to get it running, I did not hot change it. So, after having the gas tank cleaned and a new battery installed, the car fired right up and started hesitantly to rise off the ground. The rear went up about halfway, when I heard a loud “bang” and she dropped like a rock, a pool of fluid spreading under it. That was when the books and the wallet came out. It wasn’t to rise again for nearly a year.

The first project was to get it to hold water. The upper radiator hose had rotted off and the antifreeze had hardened into a white concrete like substance in the openings in the block on up, so I had to replace the head, the water pump and spacer and the intake manifold. Getting all of the spheres and the pressure regulator rebuilt, the hydraulic tank flushed, and that nasty regulator return hose replaced that blew in the first place from excessive back pressure, the car rose at the first attempt. So confident was I that I had already bought plates for it. At the time, I was working in a Ford garage. The guy who rebuilt transmissions at the time, Dean and I drove it on a rally. The car went 50 miles without a problem.

Since then I have not gone through a year without completing some major project, each aimed at making the car more reliable and closer to like new. The paint and interior came much later. Being tight on the money, I did what I could as opportunities presented themselves. The paint job was done in exchange for an engine swap job on a 1968 Firebird. The seats, in English wool to match the texture and color of the original, was done in exchange for a new entrance awning and some roof work on the upholsterer’s shop outbuildings. I picked Bleu Camargue for the body and Blanc Meije for the roof to replace the sombre Gris Kandahar. They are Citroen colors from a few years later, but as I told the bodyman, I wanted the car to look like a cloud on a clear sky. And it does!

http://www.nuancierds.fr/AC 133 Gris Kandahar.htm vs http://www.nuancierds.fr/AC%20635%20Bleu%20Camargue.htm

I have gone through the entire wiring harness and replaced every questionable inch of wire and connector. The car has provisions for a backup light, a correct switch installed and the wiring run. The height correctors have actually been rebuilt twice, and the spheres just recharged along with a rebuilt hydraulic pump only 2 years ago. I have seen nearly every nook and cranny now and I am at peace with most of it.

The last major project was last year. The front calipers and parking brakes were completely overhauled and the rotors machined. The car has a nearly perfect set of European headlights on it too. Parts for the headlights came from all over the world. The buckets, glass and some of the hardware came from Canada. The lights came from Germany. The rubber gaskets came from England. The turning parts came from Sweden and the attaching parts from Australia. This is truly a world car!