by Ken Nelson…..

Many people who judge the build quality of a car

The answer is; It comes down to engineering and an intriguing bit of original design history. I was very fortunate to learn about this during a business meeting with Citroën engineers in Paris around 1984. Evidently no one else ever directly asked the company the question about the unusual fender-mounting design.

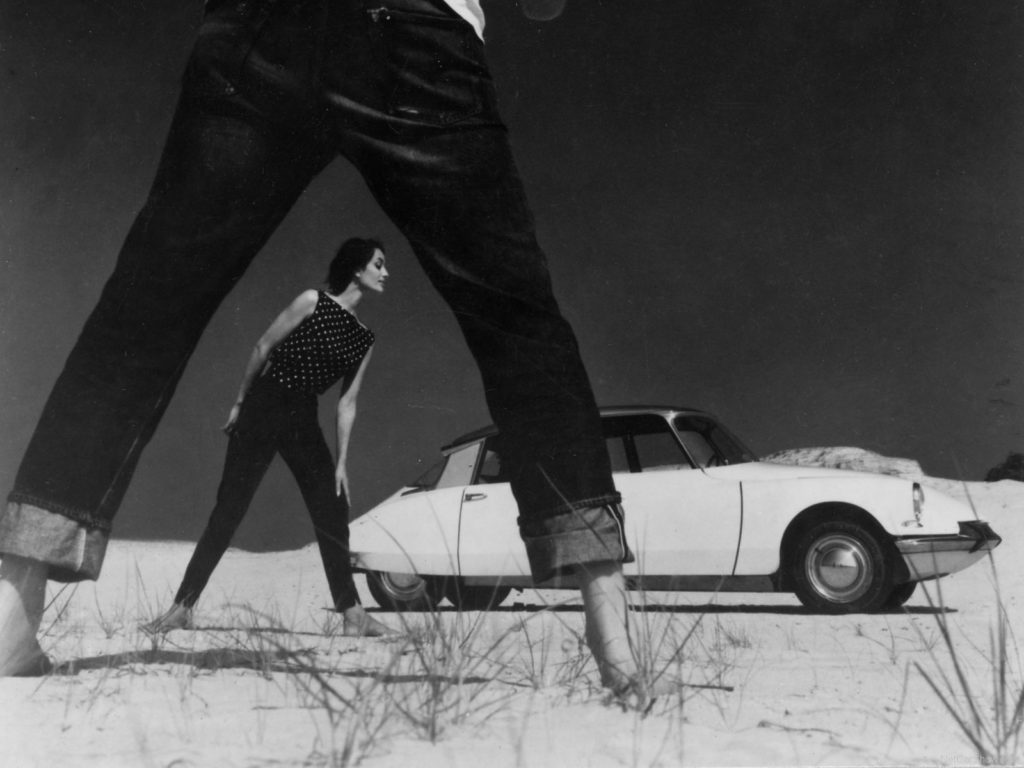

Having an unusually curious father who, in spite of being a chemist, had an extensive curiosity about things mechanical, I was introduced to DSs by Dad in 1962 in Salt Lake City when he drove home a 1958 DS19 Citromatic. First thing we did was try to understand all the out of this world features of the car. In particular, I was curious about why the fenders were mounted on rubber-cushioned pegs on the body, with wide rubber strips covering the door gaps. Nothing else in the world had been constructed this way.

Fast forward to 1984 when I was working with European manufacturers, introducing them to Dupont’s line of engineering plastics which could be used as engine & transmission parts vs the usual low-tech trim plastics. I remembered my nagging interest in the DS’s wide body gaps and so I asked the Citroën guy why they did that when tighter gaps were a sign of “higher build quality”.

He told me that as originally conceived, the DS was supposed to have PLASTIC fenders for weight reduction! The large gaps to the doors were to allow for thermal expansion in hot climates so the fenders could EXPAND without fouling the doors. The rubber fender mounts which press onto steel prongs on the body would allow the plastic fender to slide without buckling or creating rattles. After all, a lot of Traction Avants were sold into very hot climates like Africa as well very cold regions and the DS needed to function in the same wide variety of markets.

Turns out when Citroën shocked the world at the 1955 Paris Auto Show not only with the

Consequently, there was no way that many plastic body parts could be produced by the French plastics industry. They had to convert the fenders to steel because of the much faster production cycle of stamped sheet metal versus the slower thermo-forming or injection

I was frankly astonished that Citroën had so completely re-engineered a vehicle from the ground up, using materials and technology no one else had employed.

And of course, the DS nylon engine fan is the first plastic engine fan ever put into production, along with its nylon fuel line from tank to pump. But it all made sense as Dupont, a 200 yr old French company, had an American chemist who invented nylon in 1938 – in time to be used in US aircraft during WW II.

Citroën engineers were true visionaries. It’s still amazing to me that they were able to create this marvellous car without management shutting them down!

Yet, another interesting techno-info nugget supplied by Ken. (Thanks!)

I drive a ’72 DS daily and am going to a cars-n-coffee event this weekend and this knowledge will be another arrow in my informational quiver to gobsmack car lovers with.

…quite interesting! I had no clue……it all makes sense now, merci!

I’m pretty sure a plastic trunk lid is offered in the aftermarket. Curious as to why no-one seems manufactures plastic panels for the rest of the car (guessing cost). I would certainly welcome the weight reduction and rust/dent proof properties of that material – not to mention (albeit very belatedly) honoring the original engineering concept.

I am happy to ask if we can get a few more people to commit. Though I and perhaps others would prefer to wait until the English version is published.