Fascinating Finds in an Early DS

by Ken Nelson….

I showed my DS19 at Rendezvous in Saratoga Springs. Many stampings on parts of the car indicate they were manufactured in 1956. It generated a lot of interest because it had many features not found on later DS.

Some of them were outlined in the Rendezvous article in Citroënvie, and because of the immense interest expressed by many, I am pleased to delve into more detail about the things that make it one of the earliest DS in North America and with features that make it seem like a prototype.

First things that jump out —

1. Hood prop on left-hand side. It is kinked, like the slightly tapered bar on later D models.

2. Left-hand hood hinge front bolt to body goes in from underneath a flange. The fender must be off to install the bolt! Rear bolt goes in from top. (The 2nd photo shows the rear bolt installed).

3. Hood prop bracket is part of the battery/tank support, not at a point on the passenger side of the radiator as on later DS.

4. Front “mousetrap” brake calipers have return springs. These were deleted on even the earlier D models with mousetrap brake calipers.

5. There is a grease fitting on accessory shaft bearing below.

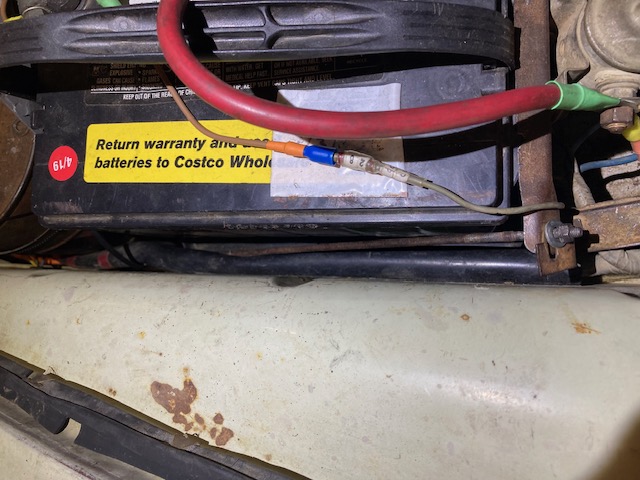

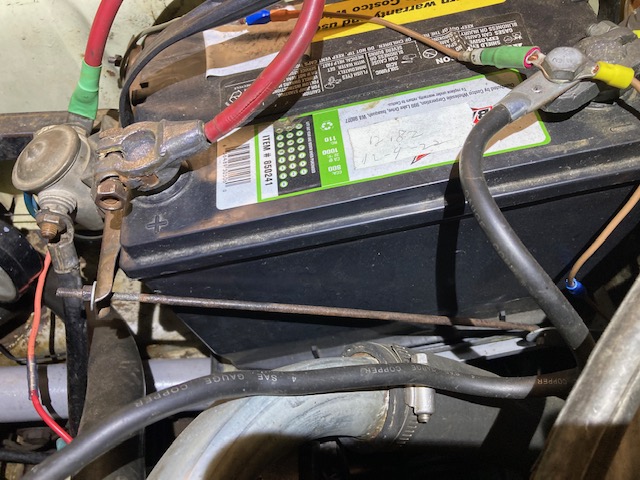

6. Battery clamped by two diagonal thin threaded rods going from rear-side top crossbar gripping the battery, to front bottom hoop loops for the rods. The crossbar holds a tin can type starter solenoid available anywhere – not a special design Citroën solenoid with nylon cover. (My original factory manual shows this bracket & solenoid only on 1956 cars.)

7. Right-hand side hood latch is released by handle through front bumper. The left-hand hood latch is released by a cable under left side of the dash. Very odd as early DS have dual hood release latches accessed through left and right sides of the front bumper, and later DS have dual hood releases by cable from the interior on both the left and right sides.

8. Window channels have tiny 5 mm screws with 8 mm heads at top. These are adjusted laterally to move glass to fit tight against top of body seal – very finicky! They’re covered by door card.

And the door window guide channels are straight, no jog at top, and lined with felt, which gets filled with crud which binds the glass.

9. Engine crank shaft & handle are mounted on the inside wall of right-hand fender. They were moved to the spare tire tray and supporting crossbar under it.

10. The fenders have an internal wall to make a fresh air tunnel to the dash vents. There is a fabric shield inside front fenders and a black metal air & water seal between each side of the front firewall and the finned fender wall. All of this was eliminated later on and replaced by a large hose. The fabric shield for some odd reason covers the back of each headlight – maybe because whole fender is fresh air tunnel and the headlight served to add some degree of warmth and dryness for night and rainy day driving with the lights on? Likely deleted as air coming from the back of the headlight was marginal!

11. Bumpers are chromed steel. Later they were all stainless around 1960.

12. Height control lever is a flat bar, not a thick rod. And the entire arrangement is different with the linkage to height correctors upside-down for rear height corrector.

13. Height corrector’s internal flow damper discs are different as they have external covers with thin steel dishes with a large center hole. They clamp the outer boots to the height corrector body. Later cars dropped the cover due to crud getting into the hole & blocking movement of the diaphragm inside the covers. (Note upside down linkage.) Later generation cars had a full rubber cover over the rubber diaphragm. You can see the crud in the photos below. It’s possible that the previous owner removed damper discs as the spool valve has some undercuts for snap rings and I don’t know if its ever been apart. As it is the front end floats weirdly on certain bumps.

14. Reservoir has only one top pipe – directly to the pump. All the other hoses & tubes enter form the bottom.

15. Reservoir filter inside is a fine brass mesh, all soldered to other brass parts — no nylon plastic & screen as in later LHS and LHM reservoirs. The filter appears to be all hand-soldered and assembled.

16. Huge bubble screen inside the tank! Never seen this before so it could be added to list of prototype details that were eliminated in later production.

17. Rear taillights are semi-rectangular, but half the thickness of later models, and have metallic center vertical bar between brake light and turning. lenses. (Taillights shown on the car are later Euro ones. as the originals are all apart awaiting restoration.)

18. At the show, André Pol pointed out a difference I missed: On each door gasket, where the jog that fits the top of door sill to glass occurs, there is a metal pad or spacer between the body pillars and the molded seal. This looks like it was intended to make sure that the junction was closed tight to avoid wind whistle. These spacers are hidden behind this jog in the rubber. I had to peel aside that junction to see them.

19. All early DSs had a water pump with low pressure hydraulic pump built into their fronts to provide power for the Citromatic shifter. The photo below shows the Gearotor hydraulic pump front section ahead of fluid feed hose on top. All pulleys cast aluminum too. This stayed the same thru at least 1959 DS19s, as I had a ’59 with this same system, so it’s not exclusively ’56, but most owners have never seen this dual purpose pump. (I bought the 1959 DS19 in 1971 for $35 off a used car lot in Wilmington Delaware and dragged all over the Midwest until about 2004. I drove it off the used car lot after fixing the dual point ignition right there on the lot. The dealer thought it was junk and was not happy when I drove it away!)

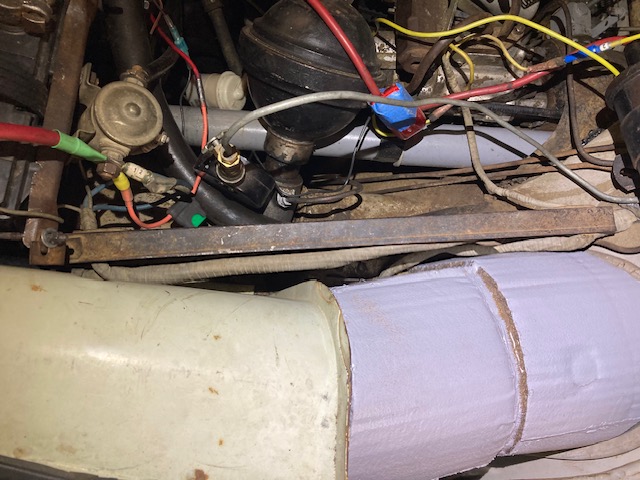

20. All early DSs had the pressure regulator hanging off the left-front bottom corner of the radiator, next to the reservoir – the most accessible place for it. The engineers had the right idea as that’s a critical control point for the hydraulics. The factory moved it later to help them assemble the cars, but not help the owners or mechanics. (Or maybe they buried it back beside the engine so in the event the pressure regulator fails and it over-pressurizes and explodes the mechanic stands a chance of survival.)

21. The right-hand fender wiring harness (for all front end wires – lights & horn) does not go across the firewall and into the rear of the right-hand fender – it goes below the reservoir on the left-hand end, and through a steel tube below the front air deflector to a point below the tire support crossbar, and is connected to terminals on the inside of the right-hand front fender. I don’t know when that harness arrangement was moved to the firewall.

22. Front bumper tip to front wheel well bracket consists of thick molded rubber space filler, with small internal nut-plate bracket, which is bolted to the bumper tip underside & bracket on wheel well. Later cars just enlarged the nut-plate bracket to do job and dropped the rubber space filler as unnecessary.

23. The front fender support sockets on this early car are more complicated than all following cars: Instead of a built-in socket for the rubber bushing and spring, the sockets on this car are separate metal cans, welded to a triangular plate. This plate carrying the socket plus rubber bushing is then attached to a large hole in the fender’s rear, and attached with 3 8mm head, 5 mm shank screws. So each fender has two triangular plates, 6 small screws and 6 nuts to secure the fender to the body prongs. That’s 14 extra parts per fender, to provide for adjust-ability of fit to the body. When the factory went to the welded-in sockets, they eliminated 24 extra parts and all the assembly required for this early car.

24. A ribbed aluminum front valence under the bumper.

25. The trunk-lid on this car is aluminum – not steel. Don’t know when they changed that.

26. The rear fender extension embellishments have a recessed pattern.

27. It has self-cancelling turn signals (roller driven off the steering column). The 1st photo shows the turn lever lifted up to start right turn. A tiny cone reduction mechanism cancels the switch, moving it to a neutral position. The 4th photo shows lever pushed down to signal a left-hand turn. Never seen this self-cancelling turn signal before and by the looks of the way it has been fitted, may have been added at some later point.

28. The original seat covering (or what remains of it) has a raised “dual chevron” seat pattern.

29. Cast aluminum backrest angle adjusters.

That’s all I can think of for now.

…very interesting and enlightening contribution, thanks Ken. Is this particular DS road worthy as is today? I notice a Panhard in the background of one of the pictures, cool car as well! Were you not at the head of the Panhard Club US at some point? These were full of innovations too I believe?

Cheers,

Dominique

Hi Dominque, yes, I have dirven the car to several local events, however, on the last run I started having a carburetor problem, and ended up being flatbedded back home by AAA. The car then started again and I drove it into my barn. I’ve been out of town since then, attending the Burning Man in the Black Rock Desert outside Reno Nev. Heading home to Mich 9/14 to take the car to our local Orphan Car show in Ypsilanti MIch – an annual show for long deceased brands. It’s held around the corner from the only Hudson dealership left in the world in Depot town Ypsilanti.

As for Panhards, want to buy one? I have around 14 for sale – went a little overboard on these, from what is to my knowledge, the first continuous production car co. in the world. From 1890 to 1891, Panhard Lavassor built 26 cars and sold extra Daimler engines they built under license to Peugeot, who was also getting off the ground way before Henry. Our titular head of the US Panhard club is John Peterson, who is a docent at the Natl motor museum in Reno Nev. This collection is what remains of the famous Harrah’s car collection which back then contained a 2CV along with 1,449 other classic cars. I’ve never headed the Panhard club, but was twice the temporary head of the Chicago Citroen club in the late ’60s and mid ’70s.

Panhard actually established the long running front engine, rear drive layout of the modern car, invented the Panhard rod used in many hotrods and racecars to stabilize the live rear axle, and also I believe established the first enclosed gearbox. Plus a Panhard won the very first world auto race in 1894, and there is a very nice statue in Paris which I only recently learned about.

To me the greatest example of “provenance” in a car is the use by the Panhard corp. of a very unique rollerbearing design used on the early flat twin aircooled engines after WWII. That rollerbearing design on the connecting rods had two different diameter rollers – with the smaller ones counter-rotating against the larger loadbearing ones, all to absolutely minimize sliding friction between rollers. The provenance bit is that I saw that very design in Leonardo’s sketch book the summer of 2005 at Leonardo’s last home – built for him by the owner of Chateau Amboise in the Loire valley of France. And that sketch dated from about 1480! Even Wikipedia acknowledges Leonardo as having invented the ball bearing, and this special dual diameter rollerbearing also came out of his marvelous mind!

One of several very good books on Panhards points out that when Panhard was forced by the French govt after the war to build economy cars instead of luxurious famously Art Deco Dynamiques, they decided to build a hotrod 2CV. Their first flat twin aircooled engines were designed to achieve 7000 rpm in 1947, an unheard of speed for a car engine, and the all-rollerbearing crank, tubular aluminum pushrods, roller lifters, torsionbar valve springs (near zero reciprocating mass vs coil springs and no failures at such high rpm), along with hydraulically adjusted valves not by heavy hydraulic lifters, but a hydraulically floated rocker arm pivoting on a hemispherical stud – THAT combination was truly innovative. My ’59 Dyna Z16 I bought from Chrysler (it joined a ’57 2CV in a Chrysler project called the “China car”) easily cruises at 85-90 on its 850 cc engine and was added to the China Car program by Bob Lutz, then Chrysler CEO – the last of the REAL car guys in the industry.

Great picture collection.

I’ve recently bought a DS19 1956.