Is eFuel Poised to Keep Our Classic Citroëns on the Road?

Progress in Europe, particularly in Germany, producing a green fuel alternative to fossil sources, has the potential to keep internal combustion engine (ICE) vehicles on the road for a much longer time than electric vehicle (EV) legislation requirements being forced on us by governments and auto manufacturers.

The actual cost to produce and operate an EV is heavily debated these days, citing the precious metals being sourced for batteries, the manufacturing cost of EVs, sustainability of the energy grid needed to supply EVs and the environmental impact disposing them at their end-of-life. Suffice to say that not everyone is going to want to endure the eventual the cost of battery replacement and normal wear repairs. And how long will they be kept operational? New car mantra seems to be ingrained in human nature.

Of course there are those like us — the classic car enthusiasts, who are prepared to keep our cars going and enjoy them for their originality. The exemption for historic vehicles seems to remain secure for now, but that could change on political whim unless a means to operate them in a “green” manner can be adopted. That solution may well be electricity-based eFuels and biogenic synthetic fuels. As an alternative to conventional fossil derived liquid fuels they show promise to be ideally suited in reducing CO2 emissions decisively and affordably in the transport and heating market – and a potentially better way than the EV to achieve climate neutrality.

Basically, the problem in the climate context of ICE vehicles is not the system of the combustion engine per se, but the fuel. With synthetic fuels, vehicles with combustion engines can be considered climate-neutral. How is this possible you ask?

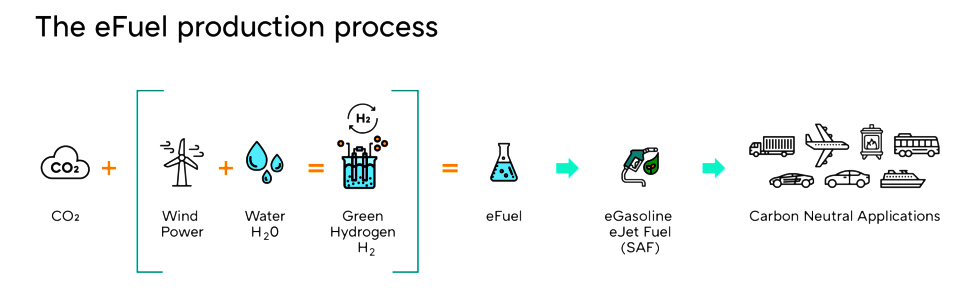

eFuel production is based on the extraction of hydrogen. This happens by means of an electrolysis process that breaks down water (e.g. seawater from desalination plants) into its components of hydrogen and oxygen. For this process and further production steps, electricity is required.

In a second process step the hydrogen is combined with CO2 extracted from the air and converted into a liquid energy carrier: eFuel. Under high pressure using a catalyst, the hydrogen binds with the CO2. Because electricity is used for the production of eFuels, the procedure is known as a power-to-liquid process: electricity is converted into a synthetic liquid that is easy to store and simple to transport.

After processing in refineries, this eFuel can be used as eGasoline, eDiesel, eHeating oil, eKerosene and eGas and can completely replace conventional fuels. Moreover, due to their drop-in capability, eFuels can be blended with conventional fuels in any ratio. Existing logistics, distribution and refueling infrastructures, such as tank farms, conventional fuel delivery tank trucks, pipelines and filling stations, can continue to be used.

The climate neutrality of eFuels derives from the fact that electricity from renewable energies is used in their production and only as much CO2 is emitted during use as was previously bound during production. eFuels can therefore make a climate-neutral contribution in all sectors where conventional fuels are currently used (e.g. transport or heating in buildings).

Some cite the energetic inefficiency of eFuel when its production utilizes otherwise usable green energy. However, this is a negligible factor if production takes place in places where green electricity is produced but cannot be transported away without enormous effort. (e.g. in the Sahara.) Once produced it (like fossil fuel) is energy that does not require battery system storage.

eFuels can solve two challenges of our energy transition: the problems of storing and transporting renewable energies. Thanks to the high energy density of eFuels, and because they can be transported at room temperature and pressure, renewable energies can be generated easily and economically around the world and transported anywhere they are needed using existing technologies. The enormous future importance of e-mobility is undisputed, but non-fossil, CO2-neutral fuels are an important building block for the estimated 1.3 billion ICE vehicles in 2035 that, if they are going to function, would best be operating with CO2-neutrally.

eFuel is proving to be viable today. A lot of experience in motorsport has been gained utilizing eFuel and it has been constantly improved and continues to be further developed. As a result, eFuel is certified according to the official fuel standard DIN EN 228.

The manufacturing process for diesel fuel also runs according to comparable principles so that a CO2-neutral diesel fuel could be produced.

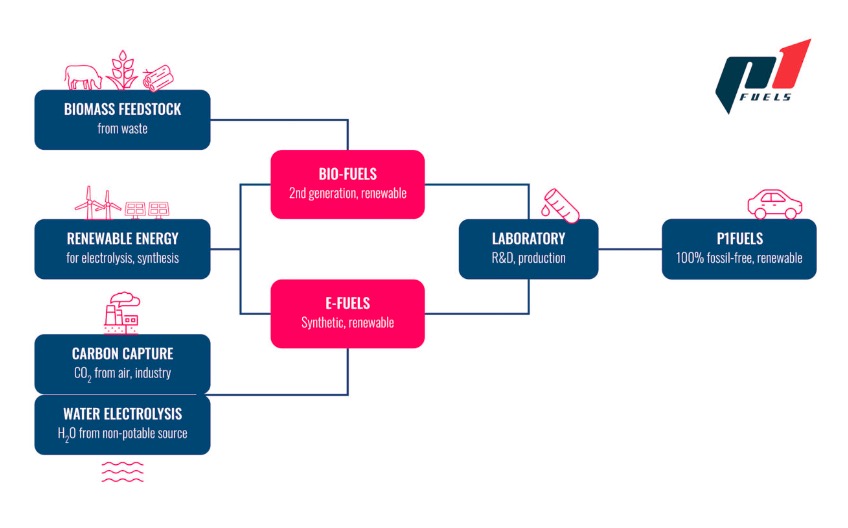

Benjamin Cuyt of P1 Fuels in Germany reports that eFuels have received more public attention in recent months and that no technical problems or difficulties have occurred with any vehicle that uses the modern, fossil-free P1 eFuel.

For example, the four-time Formula 1 world champion Sebastian Vettel repeatedly drove a 100-year-old Bentley on CO2-neutral P1 eFuel at historic events. A Formula 1 car by Nigel Mansell, has used CO2-neutral P1 eFuel. A VW T1 bus drove the entire route of the Olympic Rally from Kiel to Munich in 2022 with this modern fuel and had been doing so for six months prior, covering a distance of 3,500 km. All of this was possible without any restrictions or abnormalities.

Long terms tests of P1 eFuel when parked for months, even over the winter, have been undertaken to examine consequences for seals, injection systems, tank deposits, etc. So far, no problems have appeared.

Of course it would still be necessary to add oils in ICE vehicle operation, but here too fossil-free alternatives are already available.

In Germany gas station operator “Sprint” will become a cooperation partner of P1. In the near future, their eFuel will be available for consumers at gas pumps in Berlin. Via an app, users will immediately receive certified proof of the fuel they have filled up – also in paper form if required.

The federal and state authorities in Berlin could set an example in terms of climate policy and operate their ICE vehicles with petrol engines in their fleets with CO2-neutral eFuel.

The price of eFuel at present is presently between 5 and 6 euros higher than fossil fuel gas, but it is projected that costs will decrease. This will be made possible by producing green electricity in areas where it can be generated more cheaply, such as in consistently sunny or windy regions of the world. An adjustment to the taxation of eFuels would also contribute to lower cost since the tax rate for fuel is based on the basic assumption that it is produced from petroleum.

A tax reduction or implementation of a tax exemption for them could go hand in hand with climate-damaging fossil fuels becoming more expensive, giving an additional incentive for consumers to purchase eFuel and continue to drive ICE vehicles for their virtues.

Current eFuel production capacities are limited and increasing production to fulfill increasing demand in a location such as the Sahara could be set up comparatively quickly. The Sahara region alone offers enormous potential here, but other production sites are also possible. Also important in this context is that P1 Performance Fuels is not the sole supplier of such fuels. There are other manufacturers in Chemnitz, for example, and other projects, such as those by Porsche, are currently being planned in Chile.

There is also the ability to produce synthetic fuels in which no electricity or biomass should be used that could be used for other purposes. P1 Fuels uses biological waste as biomass at their production site in Belgium, which cannot be used in any other way. The electricity used is also 100 percent green.

The eFuel Alliance state on their website:

eFuels have been extensively researched – the scientific and technical expertise for a market ramp-up is available. However, the necessary political framework conditions are currently lacking to enable eFuels production on an industrial scale, such as CO2-based taxation of fuels, or the crediting of eFuels as a climate-neutral fuel in road transport. If the market conditions and production rules are right, eFuels can start to be produced in 2025 and steadily ramped-up to allow the complete replacement of conventional fuels in 2050.

It would help greatly if we are not coerced by those with 100% EV agendas to put in place unrealistic objectives that may well do greater damage to our climate in the long term.

The benefit of eFuels, if made readily available across the board, would enable CO2-neutral operation of combustion vehicles and in turn would allow Citroën collectors to operate their treasured classics for many decades to come.