What could possibly go wrong? — Noel Slade aftermath…

Jean-Francois “JF” Martin, Citroën specialist and owner of MARRS Automotive in Santa Clarita, CA recently had a 2CV arrive at his shop in need of repair. What he discovered from the owner was that car was “restored” by Noel Slade. We have written a few articles in Citroënvie about the poor quality of work Noel did on Citroëns, and about many who were outright swindled for cars that he never delivered.

In this case, JF did an engine swap, a rear brakes rebuild, replacement of all connector ends and fabrication to fix body sub par components and assembly. He was so shocked with the abysmal workmanship he encountered that he asked us to share the following report. There were serious safety issues on this car, so much so that he advises all owners of 2CVs that came from Noel Sale, be looked at by a competent mechanic.

This from Jean-Francois “JF” Martin:

When Bill (the owner) reached out to me it was to assess an engine noise. Even over the phone there was no doubt about rod knock. Upon delivery the car showed very well, shiny paint, very clean interior, plush carpet and an engine which was cooked.

What I was to find out after the fact made the expression “looks good from far but is far from good” made sense.

The car is on a “supposedly” 68 chassis which is seemingly a cheap knock off with late model power train and LHM brakes, late model interior.

Upon tear down of the power train, a few observations:

- Not a single washer is of the same size on the engine hardware, mixed bolts all around.

- Breather base not sealing against the block.

- Very thin oil upon engine oil drain, oil drain bolt magnet covered with metallic debris.

- Electrical has no marking or color coding, all cobbled with electric tape and low quality crimp on blue connectors from HomeDepot.

- Positive and negative leads from the battery are both 10 inches too long and zip tied.

- Late model throttle cable is not assembled properly on the fire wall, hanging unclamped.

- 3.5mm brake lines are poorly bent or routed, no attention to details.

- The brake fluid reservoir switch is not connected.

- The high beams do not work.

- Rust floating in the fuel can be seen in the inline filter.

- Fuel lines are not 6mm, clamps were over torqued. Only the top was fresh, the one going the pump was hard as a rock.

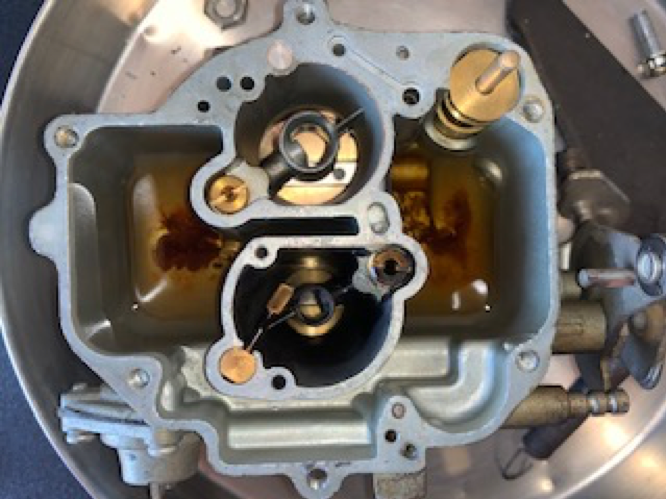

- Carburetor was rebuilt with subpar material (aluminum seal washer crushed due to over torqueing, O-ring on the outside of the idle jet (useless), thermal spacer glued to the intake manifold, nylon fuel filter crushed in its housing (at the carb intake) as it was assembled backward, Choke control unit arm bent with vise grips. Abysmal glue work on the carb fuel inlet tube and sealing compound on the float bowl plug and filter housing. Reddish mud at the base of the float bowls.

- Outboard drive shaft boots not seating in the shaft groove.

- Drive shaft mid boots clamp with plastic zip tie. Only 1 Ligarex to be found.

- Hood stay rubber grommet non-existent.

- Hood to fender panels using sheet metal hardware on the fire wall (of course Philips heads were buggered up, same goes with the M5 threads).

- Shifter linkage worn out – rubber bushing destroyed and hardware non-existent.

- Front suspension arms are from different models (right one early with cylindrical damper provision, left, late model).

- Firewall fender 19mm stud stays (at the base of the A pillar) were poorly fabricated with non metric threads, smaller size nuts (rusty castle nuts) and very thin sheet metal. Bolt arc welded as function of the welded stud. Fabricated bracket not welded in place (spot weld from the factory) but riveted in random places allowing the plate to wiggle.

- Rear trunk stay was bent, assembled upside down, no washer and cotter pins to be found.

- Driver side window holder missing, sheet metal is mangled, passenger side has 2 screws going through the plastic outer ring to keep it in place. It is clear this was there before as the inner mangled sheet metal was painted the same color as the car.

Hang on, there is more… After replacing the engine and fixing the issues above, upon first test drive, the carburetor is hard to dial in, brakes are sloppy and soft.

Upon adjustment of the rear brakes prior to a thorough bleed, I noticed the brake shoe adjusters were off and found out that one of them spun 360 degrees without any action on the shoe.

The removal of the drum allowed 2 pieces of lining to fall off and exposed 1 shoe without any friction material, the one for which the adjuster was inoperative.

Then, it took 30 min to “remove” the front hub cap bolt as it was over torqued. The thread was damaged beyond belief, the captive nut clip was bent and destroyed. Then I discovered that my 100ft.lbs impact wrench could not loosen the lug nuts and that the lug nuts were painted on the wheel. Then and only then could I get to the shaft to replace the outboard boot which was assembled incorrectly and failed due to over stress.

Hubcap bolt was stripped and needed to be cut off.

Lug nuts were painted on the wheel.

Bolt and retaining clip was over-torqued on the rim and nylon washer was missing (on all 4).

Late model throttle cable is not assembled properly on the fire wall, hanging unclamped.

Bad fabrication of supports for the fenders that attach to bottom of the firewall.

Hacked holes for the makeshift fender supports at the bottom on one side of the firewall.

Other side also the hacked hole as a makeshift fender support at the bottom of the firewall.

Throttle cable collar to the firewall went to a modified hole (too large) and was not secured.

Throttle cable hole in firewall was hacked to be enlarged with metal shavings left behind.

Outboard drive shaft boot not seating in the shaft groove and stressing the boot.

Other boot on the outboard drive shaft not seated properly.

Drive shaft mid boot clamp is plastic zip tie rather than Ligarex.

Reddish mud at the base of the carb float bowls.

The brass inlet tube to carburetor has the tube glued to it.

O-ring on the outside of the idle jet (useless).

Air mixture idle screw cap messed up.

Rust was floating in the fuel inline filter (now cleaned in the photo. Nylon fuel filter was crushed in its housing (at the carb intake) as it was assembled backward.

Electrical has no marking or color coding, all cobbled with electric tape and low quality crimp on blue connectors from HomeDepot.

Oil drain bolt magnet covered with metallic debris.

2 screws going through the plastic outer ring of passenger side window holder to keep it in place.

Driver side window holder missing, sheet metal is mangled.

Rear trunk stay was bent, assembled upside down, no washer and cotter pins to be found.

1 shoe without any friction material, the one for which the adjuster was inoperative.

Removal of the drum allowed 2 pieces of lining to fall off.

MARRS Automotive

Jean-Francois “JF” Martin, Owner

25845 Railroad Av, Unit 4

Santa Clarita, CA 91350

661-644-8612