A Past DS Feature Applied to DS Brand’s EV Future

Earlier this week the DS Brand of Stellantis showed their latest concept the DS E-TENSE PERFORMANCE. Its purpose was to promote what they have learned in Formula E racing in what they will be offering from 2024 onward as the brand switches exclusively to electric vehicles.

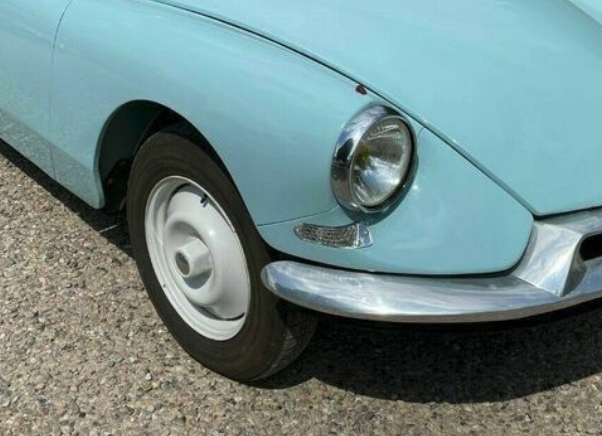

One thing that caught our eye is the single nut rim, with a center hub reminiscent of what was offered initially on the original Citroën DS and ID up until 1965 when the company switched to 5 lug nut 15” rims, ending the use of the Michelin 165 SR 400 X tire.

Why was the single nut rim discontinued on the original DS and ID? Was it a matter of manufacturing cost? Safety? The fact that garages could better handle 5 lug nut rims? Probably not so much the the latter because the 5 lug nut rims only had a small square center hole which meant they could be put on modern rotational balancing machines (like rims from virtually every other make at the time).

We asked classic Citroën DS engineering specialist Ken Nelson for his opinion on the change. Ken says:

I’m sure back around early ’60s, Michelin realized that the DS single rims were basically outmoded by all the other wheels in the world going to multiple studs, and the 165-400 mm rims were outmoding themselves re size versus the “standard” SAE 15 inch rims.

If as a customer, you were in a place where Michelins weren’t readily available, and NO one else except some Italian brands used 400 mm rims, what could you do? Citroën and Michelin were locking themselves into a corner re availability around the globe. PLUS, the single-bolt hubs had to be hellishly expensive to manufacture compared to simple discs with studs.

They must have realized that the Traction 400 mm rims were a lot cheaper to make than the more difficult to form deep draw single-bolt ones. I’ve always been astonished at the considerable lack of cost/function comparisons that Citroen didn’t seem to be concerned about! The single-bolt wheel was the one item they most likely could have done without, considering the over-the-top production of that part compared to a stud plate like every other wheel but knockoff splined wire ones.

The single-bolt hub was in many ways an ingenious way of attaching a wheel, but economically it had to add a lot of cost to the car.

The DS brand press release for the E-TENSE PERFORMANCE states;

“Our goal is to apply the experience gained in Formula E and the expertise we draw from our international titles to a project that foreshadows the electric high performance of tomorrow. It is a laboratory which will be used to analyze the behavior of the components and to develop them with a view to future industrialization.”

So in keeping with the Formula E single nut wheel hub, the designers seem to have hearkened back to a road-going means to do the same but applying it to stylish 21” avant-garde rims with more than passing resemblance to the single nut hub introduced on the DS in 1955.

Electrically the E-TENSE PERFORMANCE sports two motors totaling 600 kW or 815 hp and a torque… of 8,000 Nm! The front engine has a power of 250 kW while its rear counterpart reaches 350 kW. DS claim this combination is capable of reaching an unprecedented regeneration capacity of 600 kW, which should largely spare the traditional braking system.

Its carbon shell accommodates undercarriages similar to those of a Formula E to ensure efficient and safe behavior in all conditions. This is necessary to cope with the surge of power and torque of the motors.

Bucket seats and the steering wheel are also carried over from a Formula E.

To power everything, the DS E-TENSE PERFORMANCE counts on centrally positioned a battery specially developed for it. Its envelope made of carbon and aluminum hides an innovative chemistry, Quartz EV Fluid, developed in collaboration with Saft, a subsidiary of Total Energies.

For illumination and visual impact, the design of the light signature of the vehicle has daytime running lights of 800 LEDS!

With the DS E-TENSE PERFORMANCE, the brand intends to find solutions to lower costs, make components easier to manufacture and consider applications in series models. The next generations of the E-TENSE range will benefit from these developments,” confirms Thomas Chevaucher, Director of DS PERFORMANCE.

The prototype begins a development phase with the experience and input of two Formula E drivers, Jean-Éric Vergne and António Félix da Costa.

As I’ve mentioned in the past, when GM analyzed their first purchased DSs in ’57, and I got this straight from a GM executive engineer who was one of the guys who got the corp to buy them one day in the early ’80s at a meeting at Delco products, their accountants & engineers told management it would cost GM $10,000 in ’57 greenbacks – just to build the car, sans profit! There can’t have been the ultra precise grinding technology available in the US when GM saw the complexity of the Citroën technology nor the high volume requirements of the auto biz.

The beauty of the DS is that the engineers involved just ignored any sort of normal approach to developing a “new car”. As I interpret it, they just started from the ground up, with a clean slate directive possibly. They threw their best ideas against the wall and damn near everything stuck! To this day I cannot understand how they got the DS into production with all the radical ideas intact – except for the engine – and got them accepted by management. Anywhere else in the world I’ve gotta believe they’d have been shut down fast! I tend to believe the French back then – maybe even now – just think they’re often smarter than the rest of the world, and they often are.

When I looked into installing Dupont’s first CAD system when I moved to Detroit in ’78, and the auto industry was moving rapidly in that direction, I researched IBM’s Catia program, SDRC and the other CAD offerings, I found that Dessault – France’s aerospace co. – had invented CAD – that was a surprise! Not the US. Not IBM. IBM bit the bullet, dropped development of their system, and bought Dessault’s system. And of course it was France’s Exocet missiles the Argentinians bought to down the UK fighters in the Faulklands war –

As for the lack of a center hole on the 5 lug rims to facilitate balancing, in all my years of driving DSs, single-bolt or 5 stud, I’ve really never had a balancing problem. Thinking back on that, I have tended to conclude that Michelin tires have been so perfectly made that either they are inherently very well balanced out of the mold, or the DS suspension is SO good that I’ve never felt any real imbalance in a wheel/tire combination. Honestly, in 58 years in these cars, I can’t remember ever having one being imbalanced enough to cause me to find a way to do it!

The one thing Citroën had to change beyond going to 15 inch size when they eliminated the single-bolt rim, was to put the “dip” in the upper suspension arm when they went 5 stud. That dip near the outer end was added as the smaller diameter 15 in. rim would foul the upper arm at full down extension. Years ago, I tackled the 400 mm tire size problem by blowing up manual cross section drawings of single-bolt and 5 stud rims. One beautiful feature of the early factory manuals is that all drawings are to scale – so good that I used an expanding Xerox to blow the two cross-section drawings to full size. I then made transparencies of each rim, overlaid them, and found a spot halfway between the rim center plate and tire circle, where if I overlapped and plasma-cut a single-bolt and 5 stud 15 incher, I could overlap the rims by 1 inch, mig-weld them together, and the 1/8 in. thickness of the 5 stud would actually allow the 15 incher combo to fit a single-bolt axle at full down extension, without fouling the original upper arm. I still have the prototype – I just never went further, as I must’ve moved away from the single-bolt cars. But it should still work, if 400 mm Michelins ever stop being produced.